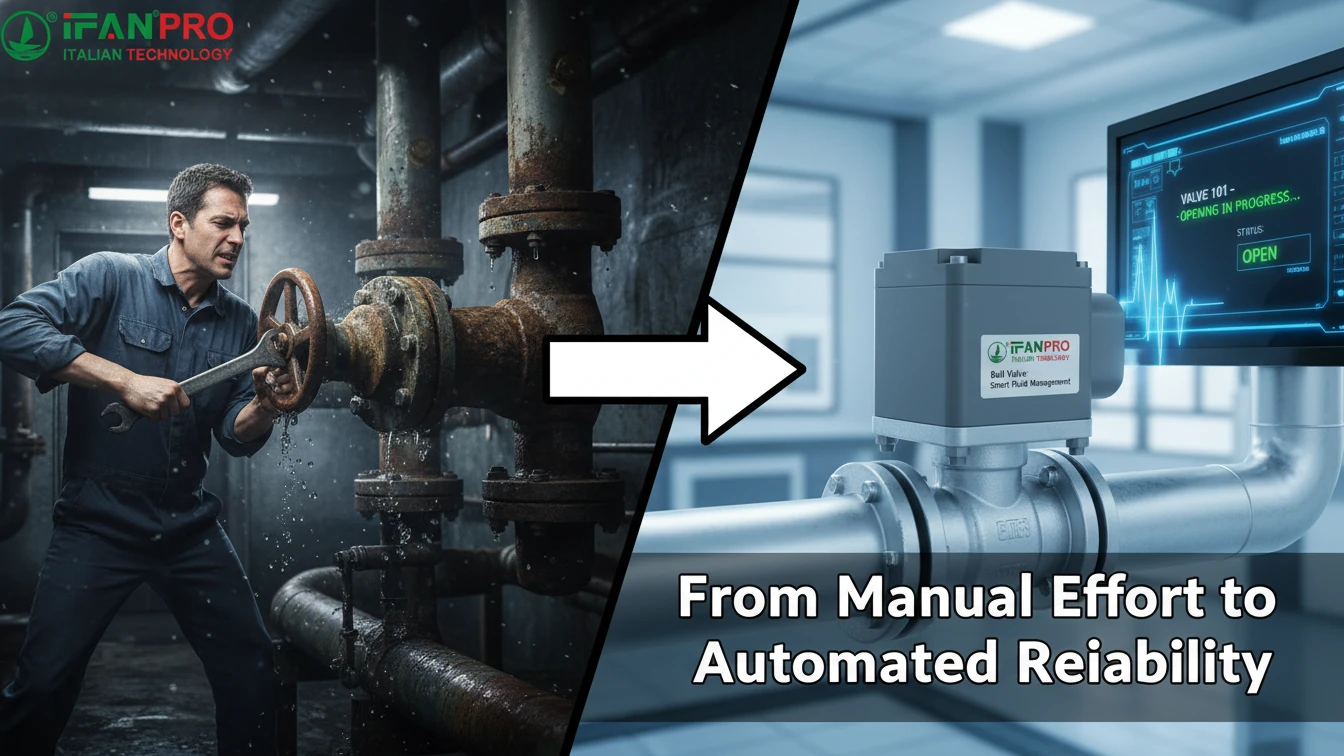

We received an urgent call: a manual valve was left slightly open, causing a costly leak. This common error is precisely why we advocate for smart valve technology.

Smart ball valves are more reliable than manual ones because they replace inconsistent human operation with automated, programmable control and continuously monitor their own health. This eliminates human error, ensures consistent performance, and provides early warnings of potential failures, preventing unexpected downtime and safety risks.

The shift from manual to smart is a shift from reactive to proactive asset management. Let’s examine the key features that deliver this superior reliability.

How Do Continuous Self-Diagnostics Monitor Valve Health Status?

A client once faced a plant shutdown because a critical manual valve seized overnight. There was no warning. Smart valves are designed to prevent such surprises.

Smart ball valves monitor their health through built-in sensors that track parameters like actuation torque, cycle count, position confirmation, and even temperature. This data is used for continuous self-diagnostics, alerting operators to abnormal conditions—like increased friction signaling wear or a sticking mechanism—long before a complete failure occurs.

From Reactive Fixes to Predictive Maintenance

The core advantage of smart valves lies in their ability to communicate their condition. Unlike a manual valve, which offers no data until it fails, a smart valve is an active participant in system health monitoring.

This monitoring happens through several key methods. First, position sensors provide absolute confirmation. The system doesn’t just send a “close” command; it receives a verified signal that the valve is 100% closed. Any discrepancy triggers an immediate alarm. Second, torque monitoring is critical. The actuator measures the force required to turn the valve. A gradual increase in required torque is a clear early sign of issues like seal wear, debris buildup, or stem corrosion. This allows maintenance to be scheduled during a planned stop, not during an emergency.

Third, smart valves log cycle counts, providing a precise record of usage against the valve’s rated lifespan. Furthermore, some advanced models include leak detection sensors or temperature sensors at the valve body, guarding against seat damage or external overheating.

Common Pain Points Addressed by Diagnostics

Based on our experience at IFAN, clients often report these failures with manual valves:

- Unknown failure timing: Valves fail without warning.

- Incorrect position assumption: An operator assumes a valve is closed, but it’s not.

- Gradual performance degradation: Increased friction goes unnoticed until seizure.

Self-diagnostics directly solve these problems by providing data and alerts.

Key Diagnostic Parameters and Their Meaning

The table below explains what common diagnostics monitor.

| Monitored Parameter | What It Tracks | Early Warning It Provides |

|---|---|---|

| Actuation Torque | The force needed to turn the valve ball. | Increasing torque signals wear, debris, or corrosion. |

| Cycle Count | The total number of open/close operations. | Alerts when the valve is nearing its design lifecycle. |

| Position Feedback | The exact open/closed (or modulated) position. | Confirms command execution; alerts on position failure. |

| Temperature | Heat at the valve body or actuator. | Warns of overheating due to process issues or actuator overload. |

| Seal Integrity (Advanced) | Pressure or acoustic signatures across the seat. | Can indicate the early stages of a seat leak. |

Practical Advice for Implementation

When choosing a smart valve for reliability, prioritize diagnostic features. Ensure the valve’s control system can integrate these alerts into your plant’s main control room or maintenance software. Start by instrumenting valves in critical applications or hard-to-reach locations. The data you gain will not only prevent failures but also optimize your entire maintenance schedule, moving from costly calendar-based checks to efficient condition-based maintenance.

Why Are Automated Actuators More Reliable Than Manual Intervention?

We’ve seen manual valves in remote locations left untouched for months, only to fail when needed. Human access is itself a reliability risk.

Automated actuators (electric, pneumatic, or hydraulic) are more reliable than manual intervention because they provide consistent, repeatable force to operate the valve precisely every time. They eliminate variability from human strength, ensure operation in inaccessible or hazardous areas, and execute commands instantly and accurately 24/7.

Consistency and Repeatability

The reliability of an automated actuator starts with its consistency. A manual valve’s operation depends on the person turning it. One operator might not apply enough force, leaving the valve partially open (a “water hammer” or leakage risk). Another might over-tighten it, damaging the seat. An automated actuator, however, applies the exact programmed force and rotation every single cycle. This repeatability ensures a perfect seal and prevents mechanical damage from improper handling.

Furthermore, automation guarantees that the valve can be operated exactly when needed. In an emergency shutdown (ESD) scenario, a smart valve with an automated actuator can close in seconds based on a sensor signal, far faster than a human could possibly respond.

Access and Safety

Reliability also means the valve must be operable under all conditions. Many valves are located in high, confined, or hazardous areas (e.g., near toxic chemicals or extreme temperatures). Sending personnel to these locations is slow, risky, and sometimes impossible in bad weather. An automated actuator allows for remote operation from a safe control room. This means valves are never left in the wrong position because they were “too difficult to reach.”

Comparing Operation Methods

Let’s compare the action of operating a valve manually versus with a smart automated system.

| Operation Scenario | Manual Valve Intervention | Smart Automated Valve |

|---|---|---|

| Routine Isolation | Technician travels to site, locates valve, operates wrench. | Operator clicks a button in the control room. |

| Emergency Shutdown | Alarm sounds, technician must find PPE, travel to valve, then act. Delay is inevitable. | System logic triggers automatic closure in milliseconds. |

| Operation in Bad Weather | Potentially delayed or deemed unsafe, risking process integrity. | Unaffected. Operation proceeds from protected control room. |

| Consistency of Torque | Highly variable, depends on individual. | Perfectly consistent, programmed for optimal seal. |

Enhancing System-Wide Reliability

Automation also enables complex, reliable sequencing. For example, a smart valve can be programmed to open slowly to prevent pressure surges (cavitation) in a pipeline—a nuanced operation impossible with a manual handwheel. This protects the entire piping system. By integrating with process sensors (like flow, pressure, or level transmitters), smart valves become active components in maintaining a stable, safe, and efficient process loop, which is the ultimate definition of system reliability.

How Does Reduced Human Error Enhance Overall System Reliability?

A miscommunication led to the wrong manual valve being closed during a maintenance event, causing a separate production line to stop. Human error is the largest unpredictable variable.

Reduced human error enhances system reliability by removing mistakes from valve operation, such as incorrect positioning, forgotten actions, or improper sequencing. Smart valves execute digital commands precisely, provide verified feedback, and can be integrated into automated safety interlocks, ensuring the process follows its designed logic without deviation.

Eliminating Direct Operational Mistakes

Human operators are excellent at decision-making but can be fallible with repetitive tasks. In complex plants with hundreds of valves, the potential for error is significant. Common mistakes include:

- Turning the wrong valve: Especially in dense fields with similar-looking valves.

- Incorrect positioning: “Quarter-turn” manual valves are particularly prone to being left in a partially open/closed state.

- Forgetting to operate a valve: Skipping a step in a startup or shutdown procedure.

Smart valves eliminate these errors at the source. Operation is done via a Human-Machine Interface (HMI) where the valve is clearly labeled, often on a process diagram. The operator selects “CLOSE” for Valve-X-101. The command is digital and unambiguous. Most importantly, the valve’s position feedback provides verified confirmation on the screen, closing the loop on the operation. There is no doubt.

Preventing Procedural and Communication Errors

Reliability extends beyond single actions to entire procedures. A manual batch process relies on checklists and verbal communications between field and control room—steps can be missed or performed out of order. Smart valve systems enable the creation of Automated Sequences or Recipe-Based Control.

For instance, a “Tank Fill” sequence can be programmed: open inlet valve A, start pump B, monitor level sensor C, close valve A at high level, stop pump B. Once initiated, the smart system executes this sequence flawlessly every time, at the correct speed and in the correct order. It removes reliance on memory, checklists, and radio communication.

The Role of Safety Interlocks

The most critical reliability enhancement is in safety. Smart valves are fundamental components of Safety Instrumented Systems (SIS). Here, they are part of hardwired or programmed logic that automatically takes the process to a safe state upon detecting a hazard.

- Example: A high-pressure sensor triggers an emergency shutdown interlock, automatically closing isolation valves. This happens independently of the basic control system and any human operator reaction.

A manual valve simply cannot participate in such a fast, deterministic safety loop. By removing the need for human judgment and reaction time in critical scenarios, smart valves dramatically reduce the probability of a catastrophic safety incident.

Practical Implementation Strategy

To leverage this, start by identifying valves involved in frequent procedures or critical safety functions. These are the best candidates for automation to reduce human error. Training for operators should then shift from how to operate the valve to how to manage and supervise the automated system, interpreting diagnostics and responding to alerts—a higher-level, more reliable role.

What Design Features Ensure Operation in Harsh Environments?

We supplied valves for a coastal wastewater treatment plant where salt spray and humidity destroyed standard equipment within a year. Harsh environments demand robust design.

Smart ball valves ensure operation in harsh environments through design features like robust sealing (IP67/IP68 ratings), corrosion-resistant materials (stainless steel, special coatings), wide temperature range components, and certifications for hazardous areas (ATEX, IECEx). These features protect the sensitive electronics and mechanics from dust, water, chemicals, and explosive atmospheres where manual operation is most difficult and dangerous.

Protection Against the Elements

A manual valve might survive a harsh environment by being a simple block of metal, but its operability is often compromised. A handwheel can freeze, corrode, or become clogged. A smart valve, however, must protect its “brain”—the actuator and electronics—while still functioning.

The first line of defense is the Ingress Protection (IP) rating. A high IP rating (like IP67 for dust-tight and immersion resistance up to 1m) ensures that moisture, dust, and corrosive agents cannot penetrate the actuator housing. This is crucial for outdoor, marine, or dusty industrial applications.

Material and Construction for Corrosion Resistance

The valve body and actuator housing materials are selected for the specific environment. For example:

- 316 Stainless Steel: Standard for marine, chemical, and food-grade applications due to excellent corrosion resistance.

- Epoxy-Coated or Painted Actuators: Provide an extra barrier against chemical splash and UV degradation.

- Seals and Gaskets: Made from Viton, EPDM, or PTFE to withstand specific chemicals, oils, or extreme temperatures without degrading.

Built for Temperature Extremes

Electronic components have defined operating temperature ranges. Smart valves designed for harsh environments use components rated for extended ranges (e.g., -40°C to +80°C). Heating elements or insulation can be added for very cold climates to prevent freezing, while heat sinks or reflective coatings help in high-temperature settings.

Safety in Hazardous Locations

Perhaps the most critical harsh environment is a potentially explosive one (with flammable gases, vapors, or dust). Sending a person to operate a manual valve here is a major risk. Smart valves can be certified for these areas with Explosion-Proof (Ex d) or Intrinsically Safe (Ex i) designs.

- Explosion-Proof: The actuator housing is so strong it can contain an internal explosion without letting flames escape to the outside atmosphere.

- Intrinsically Safe: The electrical energy in the circuitry is kept so low that it cannot generate a spark with enough energy to ignite the surrounding atmosphere.

Design Feature Comparison for Environments

The table below shows how features match specific challenges.

| Harsh Environment Challenge | Smart Valve Design Feature | Benefit |

|---|---|---|

| Rain, Splash, Humidity | High IP Rating (e.g., IP67/IP68) | Prevents water ingress and internal corrosion. |

| Salt Spray, Chemicals | Corrosion-Resistant Materials (SS316, coatings) | Protects structural integrity and appearance. |

| Dusty & Sandy Conditions | Dust-Tight Enclosure (IP6X) | Prevents abrasive particles from damaging gears/sensors. |

| Explosive Atmospheres | ATEX/IECEx Certification (Ex d or Ex i) | Allows safe operation without risk of ignition. |

| Temperature Extremes | Wide-Temp Components & Heating/Cooling Options | Ensures full functionality in Arctic cold or desert heat. |

Practical Advice for Selection

When selecting a valve for a harsh environment, don’t just consider the process fluid. Document the ambient conditions: average and extreme temperatures, presence of dust, chemicals, salt, or moisture, and the area’s safety classification. Share this with your supplier. A quality supplier like IFAN will help you select a product with the exact material grades, protection ratings, and certifications needed for reliable, long-term operation, turning an environmental challenge into a non-issue.

Conclusion

Smart ball valves deliver superior reliability by automating control, eliminating human error, self-diagnosing issues, and thriving in tough conditions. For intelligent, durable valves that enhance system reliability, explore the IFAN Smart Valve Series.

Recent Comments