Working with industrial clients, I’ve seen budget overruns on valve replacements sink projects. Large-diameter valves are a major investment, but PVC offers a smart way out.

Large-diameter PVC ball valves are cost-effective because the PVC material itself is less expensive than metals, and their lightweight design drastically cuts costs on installation, support, and long-term maintenance. They resist corrosion naturally, which eliminates a major source of failure and expense in harsh environments.

If you’re managing capital or operational budgets, understanding the full savings picture of PVC valves is crucial. Let’s break down where the real value lies.

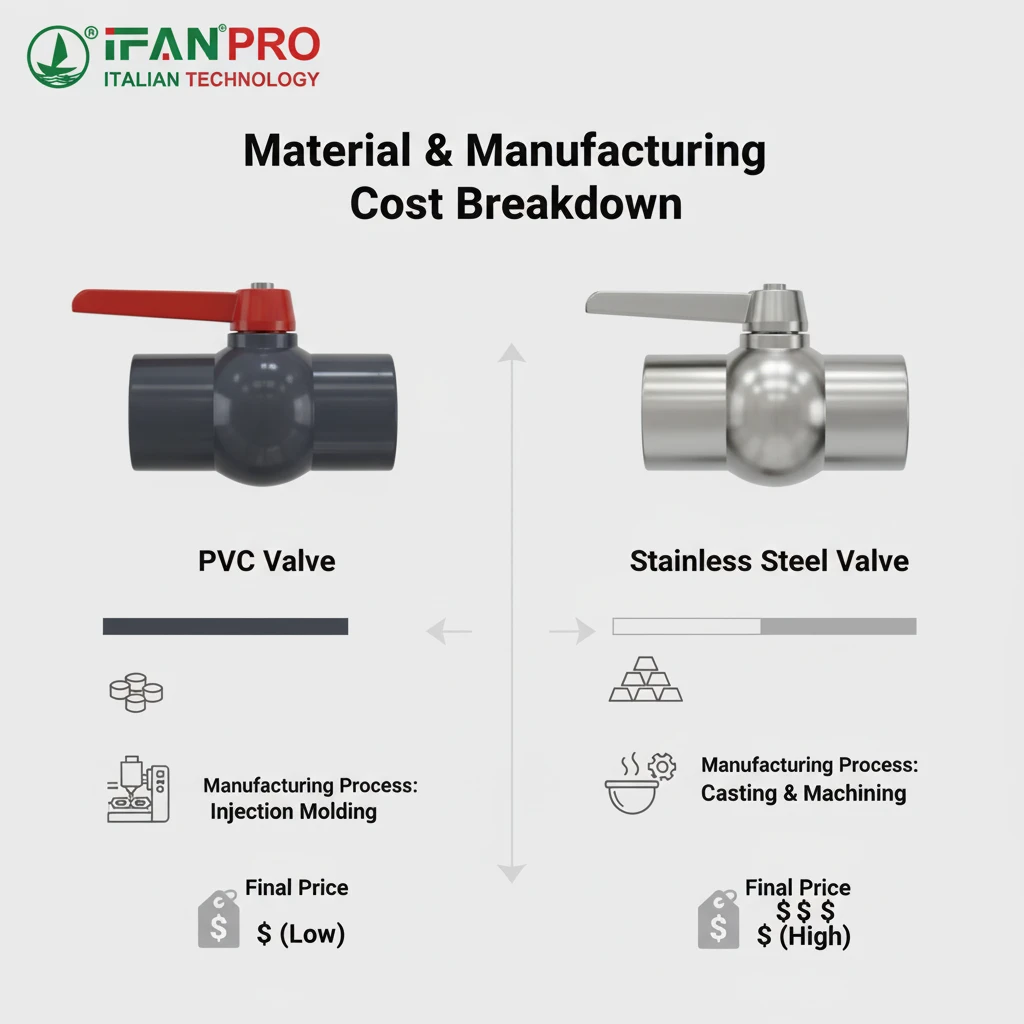

How Does PVC Material Reduce the Cost of Large-Diameter Ball Valves?

The choice of material is the first and biggest cost driver. Compared to metals, PVC changes the financial equation completely.

PVC material reduces valve costs because it is a less expensive raw polymer than metals like stainless steel, ductile iron, or brass. The manufacturing process for PVC valves, such as injection molding, is also highly efficient and automated for large volumes, leading to lower per-unit production costs compared to metal casting and machining.

The Raw Material Advantage

When we look at large diameters—think 8 inches and above—the cost of raw material becomes massive. PVC resin is fundamentally cheaper per kilogram than stainless steel or specialized alloys. This initial savings on the “stuff” the valve is made from is the primary foundation of its cost-effectiveness.

But it’s not just about the price of the raw pellet. The production process amplifies these savings.

Efficient Manufacturing Processes

Manufacturing large metal valves is labor and energy-intensive. It involves casting, which requires creating molds for each size, followed by extensive machining to create smooth ball seats and precise connections. This process generates significant waste material (metal shavings) and consumes a lot of power.

In contrast, large PVC valves are often made through injection molding. Once the high-precision steel mold for a valve size is created, the process is extremely efficient. PVC pellets are melted and injected into the mold under high pressure, forming the entire valve body in one seamless cycle with minimal waste. This automation allows for high, consistent output at a lower cost per unit.

Comparing Initial Purchase Price

The table below illustrates the typical price difference you can expect at the point of purchase.

| Valve Material (12-inch Ball Valve) | Relative Material Cost | Key Manufacturing Factor |

|---|---|---|

| PVC | Lowest | Efficient injection molding; low-cost raw polymer. |

| Ductile Iron | Moderate to High | Energy-intensive casting; requires internal lining/coating for corrosion protection. |

| Stainless Steel 316 | Highest | Expensive alloy material; intensive machining and labor required. |

This lower upfront cost frees up capital for other parts of your project. However, as we’ll see next, the purchase price is just the beginning of the savings story.

Why Are Large-Diameter PVC Ball Valves Cheaper to Install and Maintain?

The true cost of a valve is revealed during installation and over its lifetime. PVC’s physical properties make every step cheaper.

Large-diameter PVC ball valves are cheaper to install and maintain because they are up to 80% lighter than metal equivalents. This eliminates the need for heavy lifting equipment, reduces labor time, and requires simpler, lighter support structures. For maintenance, their corrosion resistance means no painting, lining repairs, or frequent part replacement due to rust.

Installation Cost Savings

Imagine installing a 12-inch valve. A stainless steel one can weigh hundreds of pounds, requiring a crane, a crew of workers, and carefully engineered supports. Now, compare that to a PVC valve of the same size. One or two workers can often maneuver it into place by hand.

This has a direct impact on your project budget:

- No Heavy Machinery: You save on crane rentals and the associated site logistics and safety requirements.

- Faster Installation: Less time spent rigging and positioning means your crew moves faster, reducing labor hours.

- Simpler Supports: You don’t need heavy-duty I-beams to hold up a lightweight PVC valve. Lighter, less expensive bracketing is sufficient.

Drastic Reduction in Lifetime Maintenance

After installation, metal valves in corrosive environments (handling chemicals, saltwater, or aggressive wastewater) begin a constant battle with corrosion. This leads to predictable and expensive maintenance cycles:

- Regular Inspections & Painting: Metal valves need to be checked for rust and repainted to protect them.

- Lining Failure: Iron valves often have epoxy or cement linings. When these linings crack or wear, the valve body corrodes from the inside, leading to failure and costly replacement.

- Seizure & Leakage: Corrosion can cause the ball and stem to seize, making the valve inoperable. It can also eat away at seals and seats, causing leaks.

PVC valves sidestep all of this. They are inherently inert to a wide range of corrosive chemicals and will not rust. This means:

- No Protective Coatings: They never need to be painted.

- No Internal Lining: The valve body itself is the corrosion barrier.

- Predictable Performance: The seals and seats wear out from normal use, not from being destroyed by corrosion, leading to longer service intervals.

Lifecycle Cost Comparison

This table shows where the savings accumulate over 10 years.

| Cost Category | PVC Ball Valve | Ductile Iron (Lined) Ball Valve |

|---|---|---|

| Initial Purchase Price | $1,000 | $1,800 |

| Installation (Labor & Equipment) | $500 | $2,500 |

| 10-Year Maintenance (Inspections, Painting) | $200 | $1,500 |

| Potential Premature Replacement | Unlikely | Likely (if lining fails) |

| Total 10-Year Cost | ~$1,700 | ~$5,800+ |

The numbers show that the installation and maintenance savings overwhelmingly justify the initial choice.

What Makes PVC Ball Valves Durable and Cost-Efficient for Industrial Use?

Durability is not about being the strongest, but about being the most suitable. In many industrial settings, PVC’s specific strengths translate directly to long-term savings.

PVC ball valves are durable and cost-efficient for industrial use because they excel in applications where corrosion is the primary enemy. Their full-port design minimizes pressure drop and clogging, and their smooth interior surface resists scaling and buildup. This combination reduces system strain, prevents downtime from clogs or failures, and extends service life with minimal intervention.

Durability in Corrosive Environments

For industries like water treatment, chemical processing, mining, and agriculture, corrosion is the number one cause of valve failure. A valve can be incredibly strong, but if it turns to rust, its strength is irrelevant. PVC’s chemical resistance makes it the more durable choice in these contexts. It outlasts unprotected iron or steel valves by years, sometimes decades, avoiding the high cost of unplanned shutdowns and emergency replacements.

Design Features for Long-Term Performance

Beyond material, the design of PVC ball valves contributes to their cost-efficiency:

- Full-Port Design: Most large-diameter PVC ball valves are full-port, meaning the opening through the ball is the same size as the pipe. This allows for unrestricted flow, which reduces energy loss (lower pumping costs) and prevents sediment from catching and building up at the valve, a common cause of clogging in reduced-port valves.

- Smooth Bore: The smooth interior surface prevents scaling and mineral deposits from adhering. In applications like irrigation or wastewater, this prevents gradual flow restriction that can impair system performance over time.

Application-Specific Advantages

Let’s look at where this durability pays off:

| Industrial Application | Key Threat | How PVC Valve Saves Cost |

|---|---|---|

| Water & Wastewater Treatment | Chlorine, sulfides, acidic/alkaline fluids. | No corrosion means no leaching of metals into water, no lining repairs, and predictable lifespan. |

| Chemical Transfer | Wide range of aggressive acids, bases, and solvents. | Superior chemical resistance chart allows safe, long-term handling without degradation. |

| Agricultural Irrigation | Fertilizers, soil acids, and constant sun (UV). | UV-stabilized PVC formulations resist breakdown; smooth bore prevents clogging from debris. |

| Mining & Slurry Lines | Abrasive slurries and corrosive leachates. | Smooth surface resists scaling; corrosion resistance maintains integrity in harsh wet environments. |

The Real Cost of Downtime

The ultimate cost-efficiency of a durable valve is in preventing downtime. An unexpected valve failure in an industrial process can stop a production line, delay a batch, or cause environmental containment issues. The cost of this downtime—lost product, idle labor, emergency repair crews—can dwarf the price of the valve itself. By choosing a valve material like PVC that is matched to the environment, you are investing in system reliability and predictability.

How Do You Evaluate the Total Cost Savings of PVC Ball Valves?

Making a smart purchasing decision requires looking beyond the price tag. A simple framework can help you quantify the real savings.

You evaluate the total cost savings of PVC ball valves by calculating the Total Cost of Ownership (TCO). This means adding the initial purchase price to all estimated costs over the valve’s service life, including installation, maintenance, energy impact, and potential downtime. For large-diameter valves, the savings on installation, corrosion avoidance, and reliability often make PVC the lowest TCO option.

Building Your Total Cost of Ownership (TCO) Model

To make a fair comparison, create a simple spreadsheet. Project costs over a meaningful period, like 10 or 15 years. Here are the key factors to include for each valve option (PVC vs. Metal):

1. Initial Costs:

- Valve Purchase Price

- Cost of Ancillaries (special flanges, adapters)

- Freight/Shipping (lower for lightweight PVC)

2. Installation Costs:

- Labor Hours Required

- Cost of Lifting Equipment (crane rental)

- Cost of Support Structures & Foundations

3. Operational & Maintenance Costs (Annual Estimates):

- Preventive Maintenance (inspections, lubrication for metal valves)

- Corrective Maintenance (repair kits, part replacement)

- Protective Upkeep (sanding and repainting metal valves)

- Energy Cost Impact (full-port PVC valves may reduce pump load)

4. Failure & Downtime Costs (Risk-Based):

- Probability of Failure

- Cost of an Unplanned Shutdown (lost production, emergency labor)

- Cost of Full Valve Replacement

A Practical TCO Calculation Example

Let’s compare a hypothetical 10-inch valve in a water treatment plant.

| Cost Factor | PVC Valve | Ductile Iron Valve (with lining) |

|---|---|---|

| Purchase & Delivery | $800 | $1,400 |

| Installation | $400 | $1,800 |

| Annual Maintenance | $50 (inspection only) | $300 (inspection + painting) |

| Lining Replacement (Year 7) | $0 | $2,000 (part + labor) |

| Risk of Downtime Cost | Low ($500 estimate) | High ($2,000 estimate) |

| Total 10-Year Cost | $800 + $400 + (10*$50) + $500 = $2,200 | $1,400 + $1,800 + (10*$300) + $2,000 + $2,000 = $10,200 |

Key Questions for Your Evaluation

Before you decide, ask these questions about your specific project:

- What is the fluid? Is it corrosive? Abrasive? (Check PVC chemical resistance charts).

- What are the site conditions? Humid, salty air? Underground? This affects corrosion risk.

- What is the cost of downtime? How critical is this line to continuous operation?

- What is your internal labor rate? Heavy valves demand more expensive time.

By running a TCO analysis, you move the conversation from “Which valve is cheaper today?” to “Which valve saves us the most money over its life?” The answer, for a vast range of applications, is PVC.

Conclusion

Large-diameter PVC ball valves save money at every stage: purchase, installation, and long-term operation. For a reliable supply of high-quality, cost-effective PVC ball valves, contact IFAN to discuss your project specifications.

Recent Comments