I once saw a costly stainless steel valve fail in months, eaten away by a chemical it wasn’t meant to handle. That mistake taught me that true corrosion resistance means matching the material to the service.

Yes, large PVC valves are highly corrosion-resistant for chemical plants when selected correctly. Unlike metals, PVC does not electrochemically corrode. Its resistance comes from its inert polymer structure, which withstands a wide range of aggressive acids, alkalis, and saline solutions, making it a durable and cost-effective choice for many corrosive services.

However, “corrosion-resistant” is not a universal guarantee. Let’s break down exactly how, when, and why PVC valves work so well in these harsh environments.

What Chemical Resistance Properties Make PVC Valves Suitable for Plants?

Many plant managers worry about unexpected valve failure. The right material choice prevents this.

PVC valves are suitable because the polyvinyl chloride material is inherently non-conductive and inert. It does not react with a vast range of oxidizing and reducing agents, salts, and acids that quickly damage metal valves. This chemical inertness, combined with a smooth interior that resists scaling, provides long-term reliability in corrosive fluid handling.

The Science Behind the Inertness

At its core, corrosion in metals is an electrochemical process. Ions flow, and the metal slowly dissolves. PVC valves avoid this problem entirely because they are plastics, not metals. They do not conduct electricity, so this type of corrosion cannot start.

The resistance of PVC comes from its molecular structure. The chlorine atoms in the polymer chain create a very stable and inert material. This stability means it does not easily give up or accept electrons in chemical reactions. So, when many aggressive chemicals flow through a PVC valve, they simply do not react with the valve body. The valve stays intact, while the chemical passes through unchanged.

Key Performance Advantages

This leads to several practical advantages in a plant setting:

- Wide Compatibility: PVC resists attack from a broader range of chemicals compared to many common metals. For example, stainless steel is weak against chlorides, but PVC handles them very well.

- No Contamination: Because it is inert, PVC does not leach metal ions into the process fluid. This is critical in industries like pharmaceuticals or fine chemicals where product purity is essential.

- Smooth Flow: The interior surface of a PVC valve is very smooth. This does two things. First, it minimizes pressure drop. Second, and more importantly, it prevents corrosive salts or crystallizing materials from sticking and building up scale, which can create localized corrosive spots under deposits.

How PVC Compares to Common Metal Valves

The table below shows why PVC is often the better choice for corrosion resistance.

| Valve Material | Corrosion Mechanism | Weak Against | Strong Against |

|---|---|---|---|

| PVC | Non-corrosive (Inert) | Strong solvents, some aromatics | Acids, alkalis, halides, salts |

| Carbon Steel | Rust (oxidation), Galvanic | Acids, water, oxygen | Caustics, hydrocarbons (dry) |

| Stainless Steel 304 | Pitting, Crevice Corrosion | Chlorides, reducing acids | Oxidizing acids, nitric acid |

| Bronze | Dezincification | Ammonia, some acids | Sea water, weak alkalis |

A Crucial Consideration: Temperature and Concentration

It is vital to remember that PVC’s chemical resistance depends on two key factors: the concentration of the chemical and the temperature of the service. A chemical that PVC handles well at room temperature might attack it at 60°C. Always consult a chemical resistance chart specific to the PVC compound used by the manufacturer, like those provided by IFAN, for your exact application conditions.

Which Aggressive Chemicals Can PVC Valves Safely Handle in Industrial Use?

Choosing the wrong valve material for a chemical line is a major operational risk.

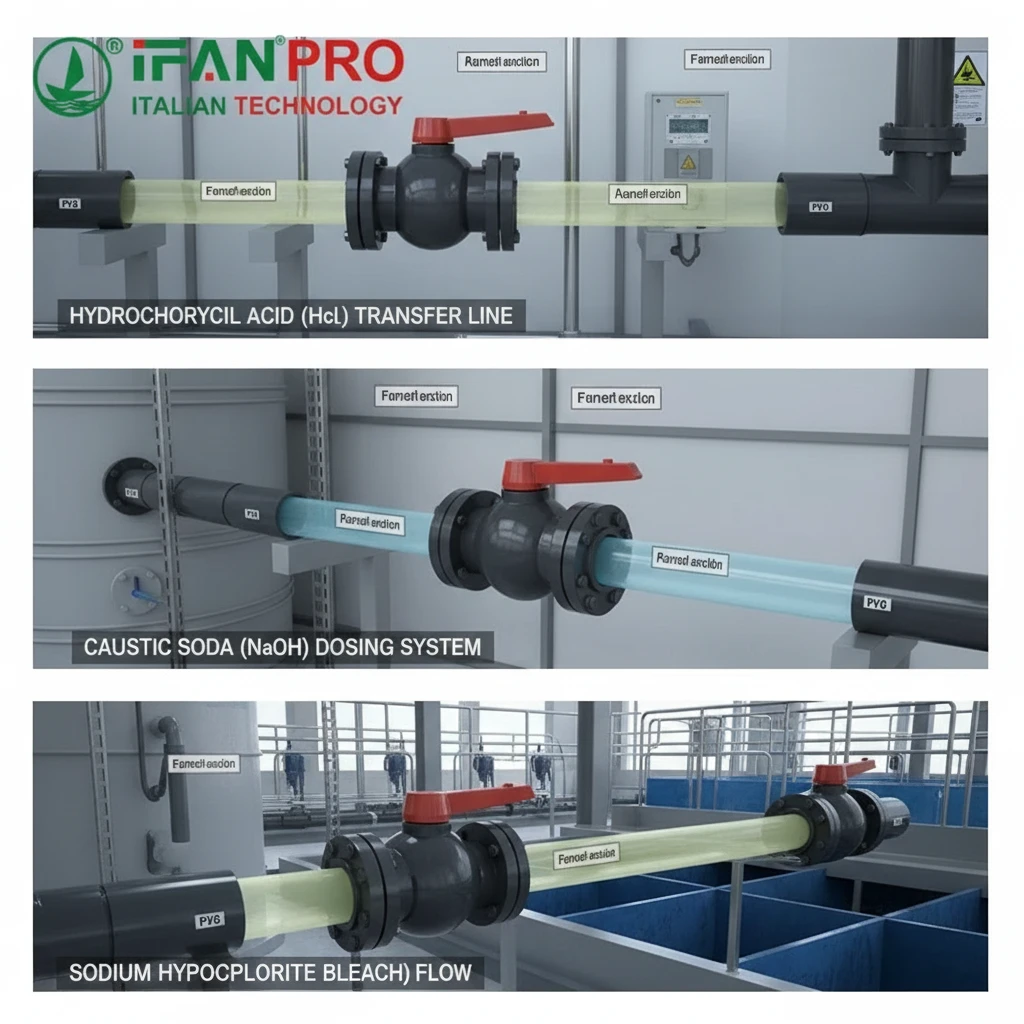

PVC valves can safely handle many aggressive industrial chemicals, including hydrochloric acid, sulfuric acid (at moderate concentrations), sodium hydroxide, bleach (sodium hypochlorite), and various salt solutions. Their excellent resistance to inorganic acids, alkalis, and oxidizers makes them ideal for water treatment, chemical processing, and effluent handling applications.

Resistance to Acids and Alkalis

Based on IFAN’s project experience, PVC is a workhorse material in plants dealing with corrosive inorganic fluids. Its performance against acids is particularly noteworthy.

For instance, hydrochloric acid (HCl) at most concentrations and at ambient temperature has virtually no effect on PVC. This makes PVC valves the standard choice for HCl handling lines, pickling operations, and acid neutralization systems. Similarly, sulfuric acid (H₂SO₄) can be handled at concentrations up to around 70-80% at room temperature. Beyond that, or at elevated temperatures, alternative materials like CPVC may be needed.

On the alkaline side, PVC shows outstanding resistance to sodium hydroxide (caustic soda) and potassium hydroxide across a wide range of concentrations. This is a key advantage over aluminum or zinc, which are severely attacked by alkalis.

Handling Oxidizers and Salts

PVC also performs well with many oxidizing agents and salts, which are notorious for causing pitting and stress corrosion cracking in stainless steels.

Sodium hypochlorite (bleach), a common disinfectant and oxidizer, is routinely handled by PVC piping and valves in water treatment plants. Brine solutions (sodium chloride) and other salt solutions that would rapidly corrode carbon steel flow safely through PVC systems without issue. This makes PVC ideal for desalination pre-treatment, dye houses, and plating rinse lines.

Chemicals to Avoid with PVC

However, PVC is not universal. Knowing what it cannot handle is just as important. Plant engineers must avoid using standard PVC valves with:

- Aromatic Hydrocarbons: Such as benzene, toluene, and xylene.

- Chlorinated Hydrocarbons: Such as carbon tetrachloride or dichloroethane.

- Strong Solvents: Such as acetone, ethyl acetate, or MEK.

- Concentrated Oxidizing Acids: Like fuming nitric acid or oleum.

For these services, other plastics like PTFE (Teflon) or metals like Hastelloy are required.

Common Chemical Applications for PVC Valves

The table below lists typical safe applications based on IFAN’s client use cases.

| Chemical Service | Typical Concentration | Common Plant Application | PVC Valve Suitability |

|---|---|---|---|

| Hydrochloric Acid | Up to 37% | Pickling, pH adjustment, chemical synthesis | Excellent |

| Sulfuric Acid | Up to 70% @ 20°C | Battery acid, fertilizer production, drying agents | Good to Excellent |

| Sodium Hydroxide | Up to 50% | Caustic washing, scrubber systems, soap making | Excellent |

| Sodium Hypochlorite | Up to 15% | Disinfection, bleaching, odor control | Very Good |

| Brine (NaCl) | Any concentration | Water softening, ion exchange regeneration, food processing | Excellent |

Always conduct a thorough review of the specific chemical, its temperature, and possible impurities before finalizing the valve material selection.

How Do You Select PVC Valves for Specific Chemical Plant Applications?

A valve is more than just its body material. Wrong selection leads to leaks, failures, and downtime.

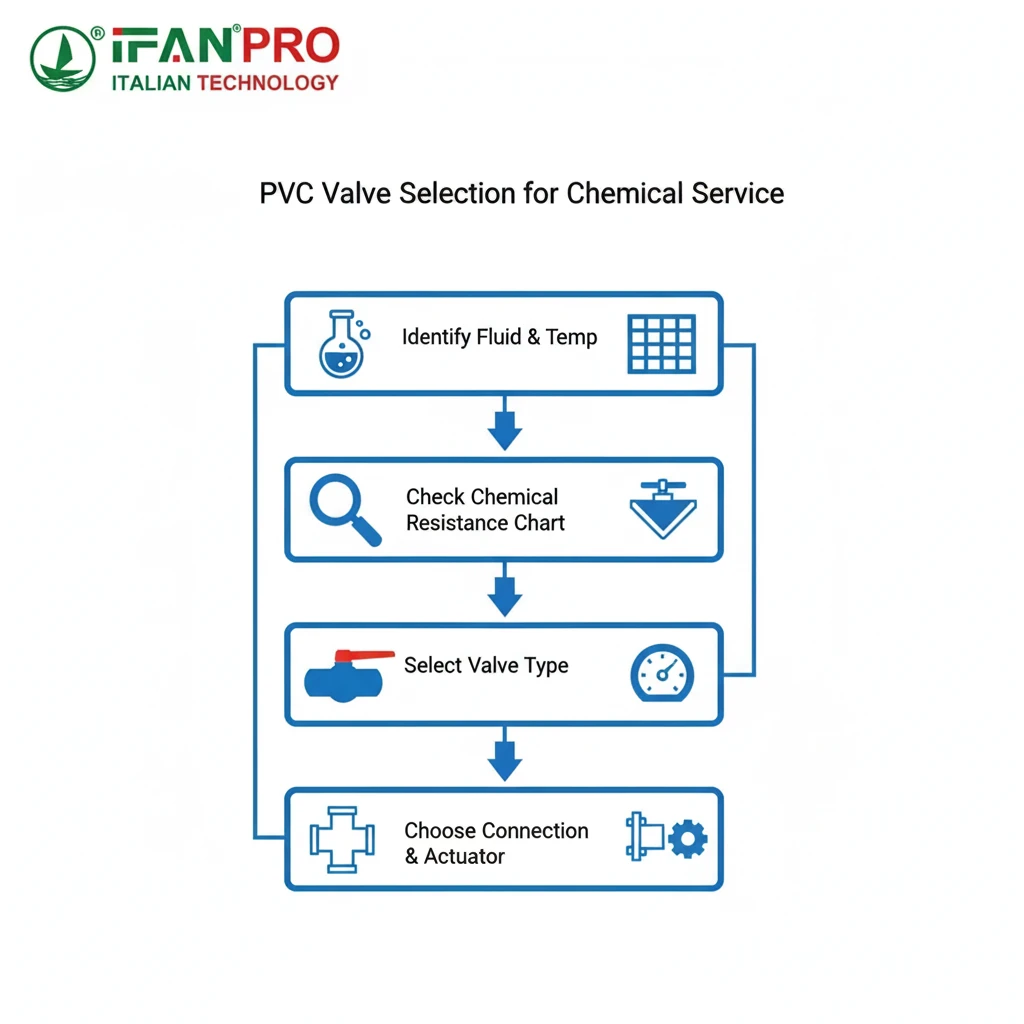

You select PVC valves by following a systematic process: First, identify the full chemical composition, concentration, and temperature of the fluid. Second, consult a detailed chemical resistance guide. Third, match the valve type (ball, diaphragm, check) to the process requirements for flow control, pressure, and actuation needs.

Step 1: Define the Service Conditions Precisely

You cannot select a valve without complete data. This is the most common mistake we see. Gathering all service parameters is the critical first step.

- Fluid Composition: List every chemical in the stream, including trace elements or cleaning agents. A small amount of a solvent can degrade PVC even if the main chemical is compatible.

- Concentration: Know the exact percentage. Resistance can change dramatically between a 10% and a 70% acid solution.

- Temperature: Note both the normal operating temperature and any possible temperature spikes. PVC’s strength and chemical resistance decrease as temperature rises.

- Pressure: Determine the system’s maximum working pressure. PVC valves have lower pressure ratings than metal ones, especially at higher temperatures.

- Flow Characteristics: Is the fluid abrasive? Does it contain solids? This affects valve trim choice.

Step 2: Choose the Right PVC Valve Type and Features

Once the fluid is confirmed compatible with PVC, you must choose the correct valve design for the job.

- Ball Valves: Best for on/off service with full, unobstructed flow. Ideal for clean fluids. Choose a full-port design to minimize pressure drop.

- Diaphragm Valves: Excellent for slurries, viscous fluids, or fluids with suspended solids. The diaphragm isolates the working parts from the fluid, preventing clogging.

- Check Valves: Essential for preventing backflow. Swing check or piston check valves in PVC are common for water and chemical lines.

- Actuation: For automated processes, select the correct actuator (electric, pneumatic) based on required speed, torque, and fail-safe mode.

Step 3: Consider Mechanical and Safety Factors

The chemical environment is just one part. The physical installation matters too.

- Pressure/Temperature Rating: Always select a valve whose rated pressure (PN) exceeds the maximum system pressure at the operating temperature. Use de-rating charts.

- End Connections: Choose between socket fusion (for a permanent, leak-free joint), threaded (for smaller sizes), or flanged (for larger, easy-to-maintain valves).

- Standards & Certifications: Ensure valves meet relevant industry standards for quality and safety. For example, in the water industry, NSF/ANSI 61 certification is often required.

- Support: Large PVC valves need proper pipe support to avoid stress on the valve body, which can lead to premature failure.

PVC Valve Selection Checklist

Use this table as a guide during your specification process.

| Selection Factor | Questions to Ask | Example for a Acid Transfer Line |

|---|---|---|

| Chemical Compatibility | Is PVC resistant to all fluid components at the operating temperature? | 20% HCl at 25°C = Compatible. |

| Valve Function | Is it for on/off, throttling, or preventing backflow? | On/Off control = Ball Valve. |

| Pressure Rating | Does the valve’s PN rating exceed max system pressure? | System: 8 bar @ 25°C. Valve PN10 = Suitable. |

| Connection Type | Does it match the piping system? | PVC Piping = Socket Fusion Ends. |

| Size & Flow | Is it the correct size to handle flow without excessive pressure drop? | 4-inch line, full flow needed = Full-Port 4″ Ball Valve. |

| Actuation | Is manual operation sufficient, or is automation needed? | Remote dosing control = Pneumatic Actuator. |

Following this disciplined process, supported by technical data from a trusted supplier like IFAN, ensures you select a PVC valve that will perform reliably for years.

What Tests Verify Long-Term PVC Valve Corrosion Resistance in Chemical Environments?

You cannot wait ten years to see if a valve fails. Specific tests predict long-term performance.

Long-term corrosion resistance is verified through standardized immersion tests (like ASTM D543), where PVC samples are exposed to chemicals under controlled temperature and time. Additional tests for tensile strength retention, dimensional stability, and visual inspection after exposure confirm the material’s integrity and predict its service life in real-world conditions.

The Core Test: Immersion and Property Change

The most direct way to test chemical resistance is to immerse the PVC material in the chemical of interest. Reputable manufacturers conduct these tests according to international standards.

In a typical ASTM D543 test, standardized plaques or bars of the PVC compound are immersed in the test reagent at a specific temperature for a set period, often 7, 30, 90, or 180 days. After exposure, the samples are removed, cleaned, and conditioned.

Then, key properties are measured and compared to their original values:

- Weight Change: This indicates if the PVC is absorbing the chemical (weight gain) or if components are being extracted (weight loss). A small change (e.g., <1%) is usually acceptable.

- Dimensional Change: Measures swelling or shrinkage. Excessive swelling can weaken the material.

- Tensile Strength & Elongation Retention: This is the most critical test. It measures how much of its mechanical strength the PVC has retained. A retention of >80% is typically considered excellent and indicates long-term suitability.

Specialized Tests for Valve Performance

Beyond testing the raw material, valves as finished products undergo other critical validations.

- Pressure Cycling Test: The valve is repeatedly pressurized and depressurized with water or another medium to simulate operational cycles. This tests the integrity of the molded body and the joint between the body and seats.

- Life Cycle (Endurance) Test: An actuated valve is opened and closed thousands of times to ensure the seat, stem, and ball/disc do not wear out prematurely.

- Burst Pressure Test: Destructive test to determine the ultimate failure pressure of the valve, ensuring a significant safety margin over the rated working pressure.

- Fire & Weathering Tests (if applicable): For outdoor installations, UV resistance tests (like ASTM D4329) ensure the PVC won’t degrade under sunlight. Certain standards may also require fire performance tests.

Interpreting Test Data for Real-World Use

Manufacturers like IFAN use data from these accelerated lab tests to create Chemical Resistance Guides. These guides are not just simple “Yes/No” lists. They often include ratings like “Excellent,” “Good,” “Fair,” or “Not Recommended,” based on the measured property retention after exposure.

For example, a guide might show:

- Excellent: <5% property change. Recommended for long-term use.

- Good: 5-10% property change. Suitable for long-term use, but monitor.

- Fair: 10-15% property change. Limited to short-term or intermittent exposure.

- Not Recommended: >15% property change or severe visual degradation. Do not use.

Key Standards for Testing and Assurance

The table below outlines common standards that help verify PVC valve suitability.

| Test Standard | What It Evaluates | Why It Matters for Chemical Plants |

|---|---|---|

| ASTM D543 | Resistance of Plastics to Chemical Reagents | Core test for chemical compatibility and long-term aging prediction. |

| ISO 4433-3 | Thermoplastics pipes & fittings – Resistance to liquids | International standard for chemical resistance classification. |

| ASTM D638 | Tensile Properties of Plastics | Measures strength retention after chemical exposure. |

| ISO 9393 | Thermoplastics valves – Pressure test methods | Validates the pressure-bearing capability and leak-tightness of the finished valve. |

| NSF/ANSI 61 | Drinking Water System Components | Certifies the valve does not leach contaminants into potable water (for relevant applications). |

When sourcing valves, ask your supplier for test reports or a detailed chemical resistance guide based on these standardized methods. This data-driven approach is the only reliable way to verify that a “corrosion-resistant” PVC valve will truly withstand your plant’s specific chemical environment for the long haul.

Conclusion

PVC valves offer exceptional and cost-effective corrosion resistance against many aggressive chemicals when selected with precise service data. For reliable, tested large-diameter PVC valves backed by expert application support, contact IFAN for your chemical plant’s next project.

Recent Comments