We get this question all the time from engineers managing large systems. The short answer is yes, but it depends entirely on the valve’s specific design and specifications.

A properly specified industrial PVC ball valve can absolutely handle high-volume flow. Its full-port design offers minimal flow restriction, and its Cv (Flow Coefficient) value is the key metric to check. For example, a 2-inch Schedule 80 PVC ball valve can have a Cv as high as 125, allowing it to manage several hundred gallons per minute with very low pressure drop.

However, not all PVC valves are equal for high-flow duty. Let’s break down the critical factors that determine true high-volume performance, so you can select the right valve with confidence.

What is the Flow Capacity and Cv Value of Industrial PVC Ball Valves?

Finding a valve that doesn’t choke your system is frustrating. We’ve seen projects where undersized valves created bottlenecks, forcing expensive replacements.

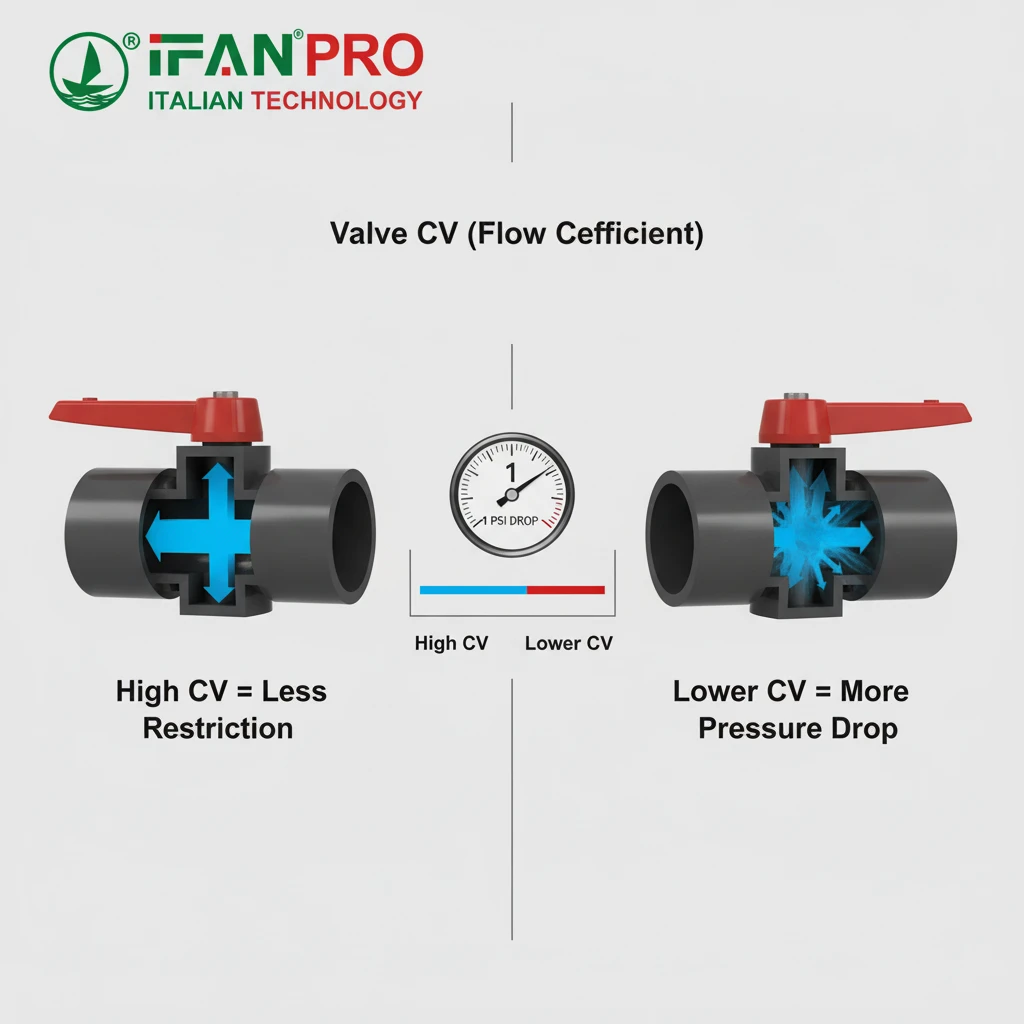

The flow capacity of an industrial PVC ball valve is best defined by its Cv (Flow Coefficient) value. Cv measures how many gallons of water per minute (GPM) will flow through the valve at a 1 psi pressure drop. Higher Cv means higher flow capacity. True “full-port” PVC ball valves have a bore diameter matching the pipe’s inner diameter, maximizing Cv and minimizing turbulence and pressure loss.

Understanding Cv: The Key Number

Think of Cv as the valve’s “flow rating.” It’s a standardized number that lets you compare different valves and sizes fairly. A valve with a Cv of 50 allows twice the flow of a valve with a Cv of 25, under the same pressure conditions.

For high-volume applications, you need a high Cv. A standard port valve might have a Cv of 55 for a 2-inch size. A full-port version of the same size could have a Cv of 125 or more. This simple difference can be the deciding factor between a system that works and one that struggles.

Full-Port vs. Standard-Port Design

This is the most important design feature for flow. The valve’s “port” is the hole through the ball itself.

- Full-Port (or Full-Bore): The hole in the ball is the same size as the pipe’s inner diameter. This creates a straight, smooth path for the fluid. It causes almost no restriction. We always recommend full-port valves for high-volume, pumping, or slurry applications.

- Standard-Port (or Reduced-Port): The hole is smaller than the pipe. This saves cost and makes the valve smaller, but it creates a restriction. It reduces flow and increases pressure drop, which can make pumps work harder.

How to Use Cv for Selection

You or your engineer will often calculate the required Cv for your application based on desired flow rate and acceptable pressure drop. You then select a valve with a published Cv that meets or exceeds that number. Reliable manufacturers provide Cv charts for their valves.

Typical Cv Values for Schedule 80 PVC Full-Port Ball Valves

| Valve Size (Inches) | Approximate Cv Value | Estimated Max Water Flow (GPM)* |

|---|---|---|

| 1″ | 60 | ~120 GPM |

| 2″ | 125 | ~250 GPM |

| 3″ | 280 | ~560 GPM |

| 4″ | 450 | ~900 GPM |

| Note: Estimated flow at a moderate 5 psi pressure drop. Actual flow depends on system pressure and fluid. |

Always ask your supplier for the certified Cv data. Choosing a valve based on this number, not just the pipe size, is the professional way to ensure it handles your required volume.

How Does PVC Material Strength Affect High-Volume Flow Handling in Valves?

A valve can have a great Cv but fail under pressure. Material strength is what holds the system together when flow and pressure are high.

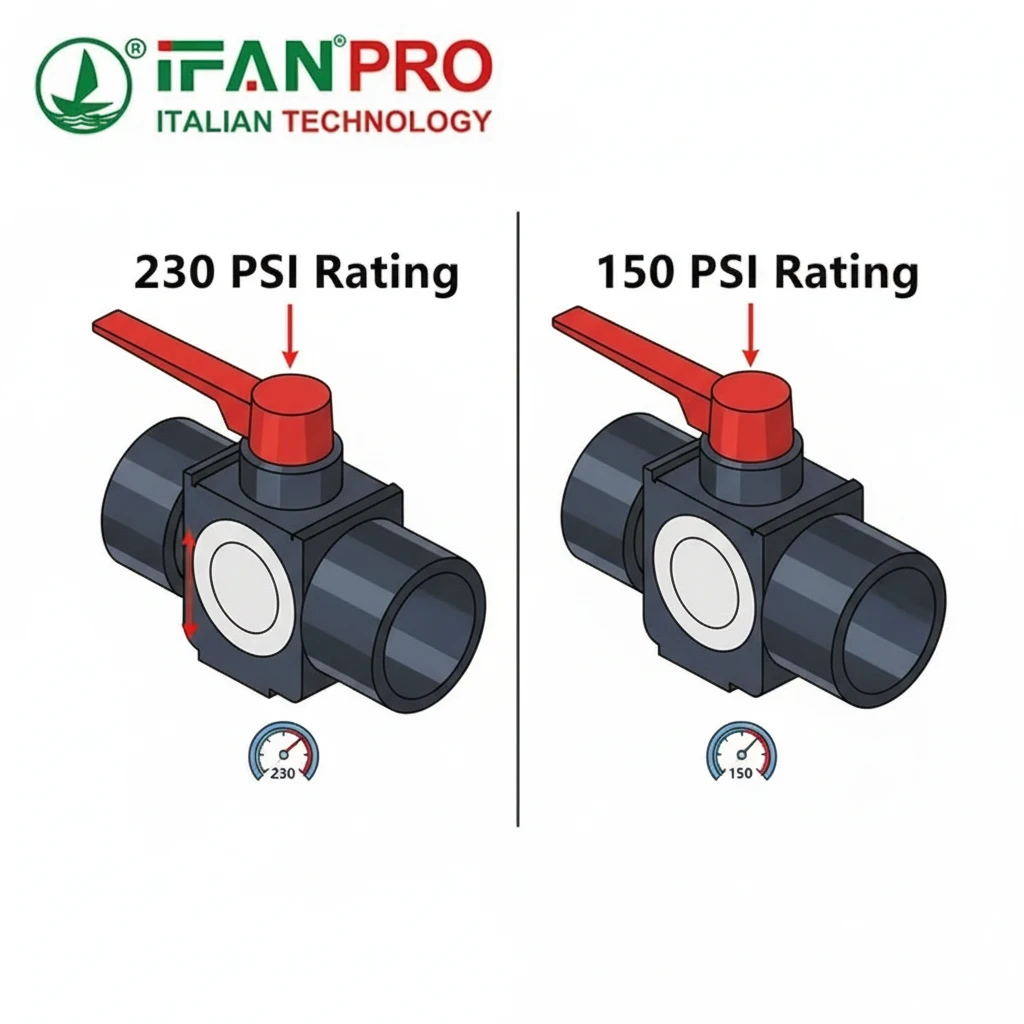

PVC material strength directly affects a valve’s ability to handle high-volume flow by determining its maximum pressure rating (PSI). Higher strength PVC (like Schedule 80 or Cell Core 80) has thicker walls and better resistance to shock, preventing rupture or deformation under the high forces of fast-moving water. Strength also ensures the ball and stem seal tightly without leaking.

Pressure Rating: The Foundation of Safety

High flow often comes with high pressure, especially from pumps. The valve must contain this pressure safely. The strength of the PVC compound and the valve’s wall thickness define its pressure rating.

- Schedule 40 PVC: Common for lower-pressure applications. A 2″ valve might have a 150 PSI rating.

- Schedule 80 PVC: The standard for industrial duty. It has thicker walls. The same 2″ valve in Schedule 80 might be rated for 230 PSI. This is the minimum we recommend for high-volume systems.

- Cell Core (Foam Core) Schedule 80: Offers the same outer dimensions and pressure rating as solid Schedule 80 but is lighter and provides better impact resistance.

Resistance to Water Hammer

High-volume flow can cause “water hammer”—a sudden pressure surge when flow stops quickly. This shockwave can crack weak valves. The inherent toughness and shock absorption of industrial-grade PVC, especially in thicker Schedule 80 designs, helps the valve survive these transient pressure spikes where brittle materials might fail.

Structural Integrity for Sealing

The force of fast-moving fluid pushes against the ball and tries to force it open. The valve’s body must be rigid enough to support the seat and stem seals without flexing. If the body flexes, it can cause leaks around the ball (seal failure) or past the stem. High-strength PVC provides the needed rigidity to maintain a perfect seal, ensuring 100% shut-off even after exposure to high flow velocities.

Key Material Strength Specifications

When evaluating a PVC valve for high flow, check these specifications related to material:

| Specification | Why It Matters for High Flow |

|---|---|

| Pressure Rating (e.g., 150 PSI @ 73°F) | The maximum sustained pressure the valve can hold. Never exceed this. |

| Schedule Thickness (80 or 80 Cell Core) | Defines wall thickness and pressure capacity. Avoid Schedule 40 for main high-flow lines. |

| Material Standard (e.g., ASTM D1784) | Ensures the PVC compound meets minimum strength, impact, and temperature requirements. Look for Class 12454-B. |

| Temperature Rating | PVC strength decreases as temperature rises. Ensure the valve’s pressure rating is suitable for your fluid’s actual temperature. |

In short, material strength isn’t just about not bursting; it’s about maintaining dimensional stability and a reliable seal under the dynamic, high-energy conditions of high-volume flow.

Which Applications Require High-Flow Industrial PVC Ball Valve Specifications?

Using a standard valve in a high-flow job leads to problems. We identify these critical applications to prevent costly mistakes.

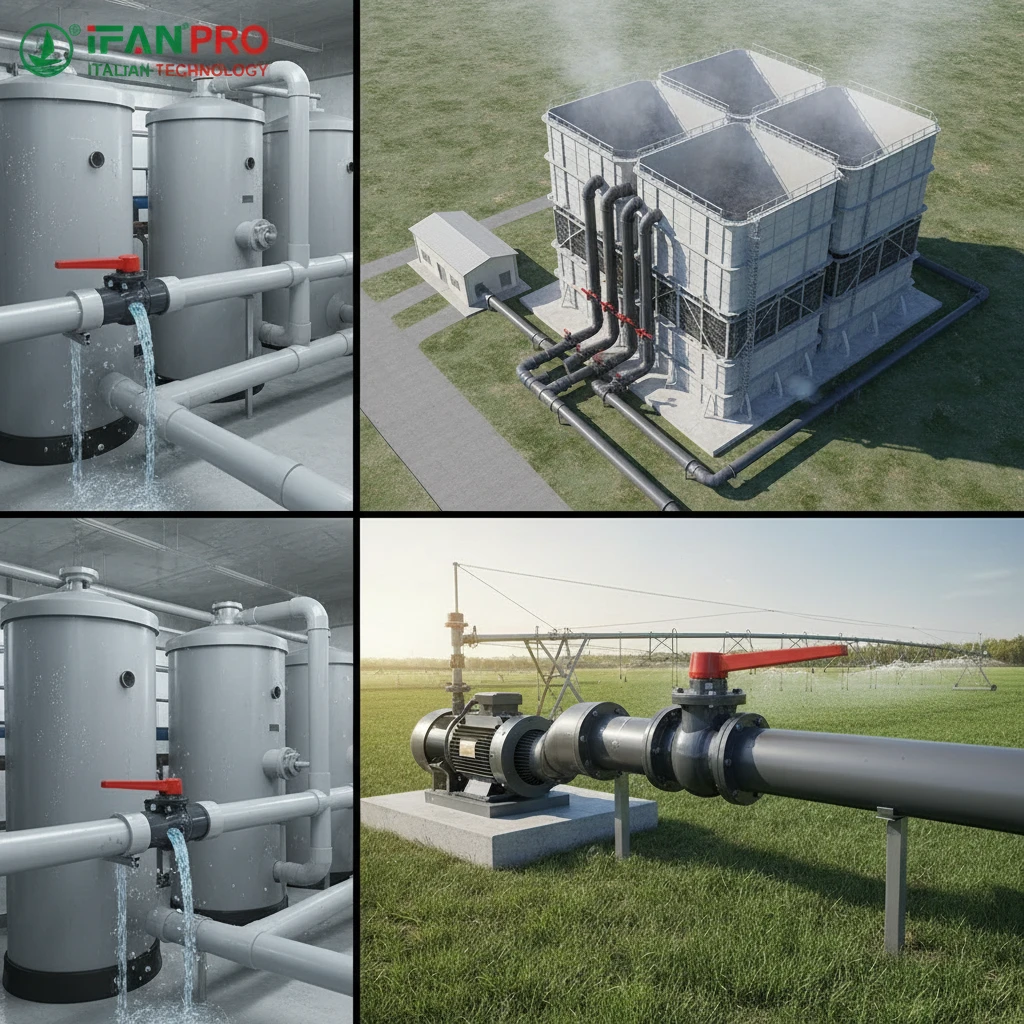

Applications that require high-flow industrial PVC ball valves typically involve moving large volumes of water or chemicals quickly and efficiently. Common examples include main supply and distribution lines in water treatment plants, industrial process cooling systems, high-capacity irrigation or agricultural systems, and bulk chemical transfer or tank filling stations.

Water and Wastewater Treatment

In this sector, moving massive amounts of water is the core operation. High-flow PVC valves are perfect for these corrosive environments.

- Plant Intake/Outlet Lines: Controlling the raw water coming into the plant and the treated water leaving it.

- Filter Backwash Lines: These lines require extremely high, rapid flow to clean filters. Valves must open and close against high pressure and flow without damage.

- Slurry and Chemical Feed Lines: Handling large volumes of additives like lime or polymers.

Industrial Process Cooling

Factories, power plants, and data centers use cooling towers and chillers that circulate huge volumes of water.

- Cooling Tower Make-up and Basin Lines: Adding fresh water to replace evaporation loss.

- Main Chilled Water Supply/Return: Isolating sections of the cooling loop for maintenance without shutting down the entire system.

- Process Cooling Lines: Directly cooling machinery or products in manufacturing.

Agriculture and Irrigation

Moving water from sources to fields at scale demands valves that won’t restrict flow and waste pumping energy.

- Main Pump Discharge Lines: The first valve after a high-capacity irrigation pump.

- Zone Control Valves for Large Fields: Managing flow to different sections of a large-scale pivot or drip system.

- Reservoir or Pond Drainage: Emptying large holding bodies of water quickly.

Chemical and Industrial Bulk Transfer

Transferring liquids from storage tanks to tanker trucks or process vessels requires fast, controlled flow.

- Truck Loading/Unloading Stations: Filling or emptying tankers efficiently.

- Tank Farm Manifolds: Directing flow between multiple large storage tanks.

- Process Vessel Fill Lines: Charging reactors or mixers with large volumes of liquid ingredients.

Why These Applications Demand Specifics

The valves in these jobs aren’t just on/off switches. They are critical components for system efficiency and safety. Using an undersized or low-pressure valve here can cause:

- Reduced System Throughput: The valve becomes the bottleneck.

- Increased Pumping Costs: The pump works harder to overcome the valve’s pressure drop, wasting electricity.

- Premature Valve Failure: Constant high velocity and pressure can erode seats, fatigue stems, or crack bodies not designed for the duty.

- Inability to Isolate: A leaking valve can’t shut off a high-flow line, causing operational shutdowns and spills.

For these critical points in your system, never compromise. Specify industrial-grade, full-port, high-Cv PVC ball valves with clear pressure ratings.

What Standards Certify Industrial PVC Ball Valves for High-Volume Performance?

Trusting a supplier’s word isn’t enough. Certifications are your independent proof that a valve is built for the job.

Industrial PVC ball valves for high-volume performance are certified by standards that test material quality, pressure integrity, and dimensional accuracy. The most important standards include ASTM D1784 for PVC material strength, NSF/ANSI 61 for drinking water safety, and manufacturer pressure tests per standards like ASTM F1970 or ISO 9393, which validate the valve’s ability to hold rated pressure without leaking.

Material Standards: The Building Block

The valve is only as good as the PVC it’s made from. Key material standards ensure consistency and performance.

- ASTM D1784: This is the fundamental standard for rigid PVC compounds. It classifies materials by their minimum strength (tensile, impact) and temperature resistance. For pressure applications, you want material classified as Cell Class 12454-B. This tells you it’s a high-impact, pressure-rated compound suitable for valve bodies.

- NSF/ANSI 61: For potable (drinking) water applications, this certification is mandatory in North America and many other regions. It tests that the valve does not leach harmful levels of contaminants into the water. This is a critical health and safety certification.

Product Performance and Testing Standards

These standards dictate how the finished valve must be designed and tested.

- ASTM F1970 / ISO 9393: These are key standards for thermoplastic pressure piping systems. They define test methods for valves, including:

- Shell Test: The valve body is subjected to internal pressure much higher than its rating to ensure it doesn’t burst.

- Seat Test: The valve is tested for leaks past the closed ball under pressure.

- Backseat Test: Tests for leaks past the stem seals when the valve is fully open under pressure.

- Cycling Test: The valve is opened and closed many times under pressure to test its endurance.

- ISO 5211: This standardizes the mounting pattern for actuators. For high-flow valves that will be automated, this ensures you can easily attach an electric or pneumatic actuator without custom brackets.

Why You Must Ask for Certifications

Certifications are not just paperwork. They are your guarantee that the valve has been independently verified to perform as advertised. In high-volume, high-pressure applications, an uncertified valve is a major risk.

Key Certification Checklist for High-Flow PVC Valves

| Standard | What it Certifies | Why It Matters for Your Project |

|---|---|---|

| ASTM D1784 (Cell Class 12454-B) | The PVC material meets minimum strength and impact requirements. | Ensures the valve body won’t crack under pressure or water hammer. |

| NSF/ANSI 61 | The product is safe for contact with drinking water. | Legal requirement for potable water systems. Ensures water quality. |

| Pressure Test per ASTM F1970 | The valve prototype passed rigorous burst, seat, and cycle tests. | Validates the manufacturer’s published pressure rating (PSI). |

| Dimensional Standards | The valve meets agreed-upon size and face-to-face dimensions. | Ensures the valve will fit your pipeline without modification. |

Always request the manufacturer’s certification documents. A reputable supplier like IFAN will have these readily available. Specifying certified valves protects your project, your budget, and your reputation.

Conclusion

Yes, a well-designed industrial PVC ball valve is excellent for high-volume flow. Focus on full-port design, high Cv values, Schedule 80 strength, and proper certifications. For reliable valves that meet these exacting standards, explore the high-flow PVC ball valve series from IFAN.

Recent Comments