I once saw a factory line shut down for two days because a cheap valve failed. This experience taught me that in industry, every component must meet strict standards.

Yes, high-quality PVC pump valves fully meet industrial standards when manufacturers specifically design, certify, and rate them for such use. Their compliance is proven through material grades, pressure ratings, and official certifications from international bodies. Therefore, these valves can safely handle demanding industrial environments.

However, not all PVC valves are equal. Consequently, let’s examine exactly how proper industrial-grade PVC valves meet the necessary requirements.

What Are the Key Industrial Standards for PVC Pump Valve Safety and Performance?

Many buyers focus only on price, not standards. This is a major risk I help clients avoid.

The key standards for PVC pump valves cover material quality, design pressure, and safe operation. Major standards include ASTM for material specifications, ISO for dimensions and testing, and NSF/ANSI for fluid contact safety. These rules ensure the valve is strong, durable, and safe for its intended industrial use.

Understanding the Different Standard Organizations

Industrial standards are rules created by expert organizations. These rules make sure products are safe and work correctly. For PVC pump valves, several groups set these important rules. Specifically, material standards are crucial because they define what the PVC plastic must be made of.

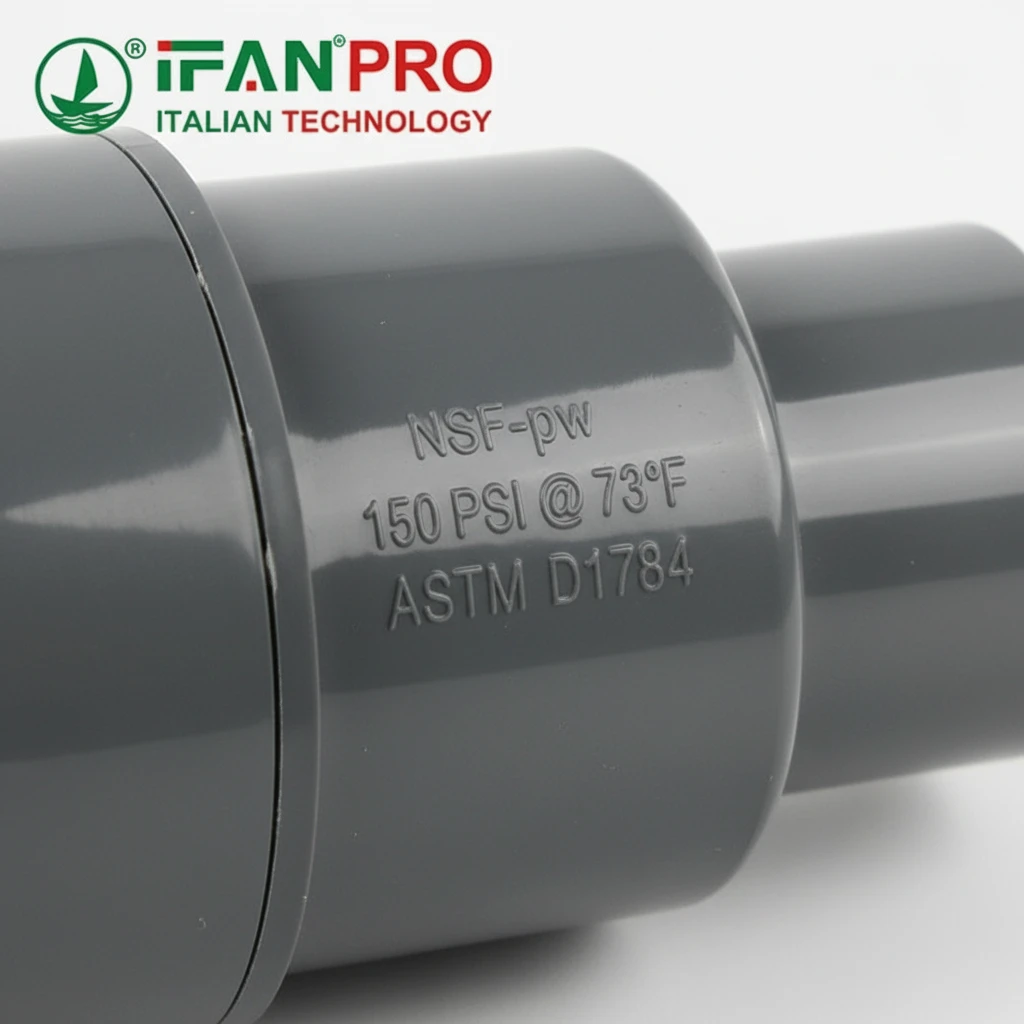

For example, ASTM D1784 is a key standard in the US. It classifies PVC compounds into “cell classes” based on properties like strength and heat resistance. An industrial valve should use a high-grade PVC, such as Cell Class 12454-B. This grade offers better impact strength and higher temperature resistance than material used for simple drain pipes.

Standards for Design and Pressure

Next, performance and design standards are vital. They tell manufacturers how to make the valve and how to test it. For instance, ISO 161 is an international standard. It sets the dimensions for thermoplastic pipes and fittings. As a result, this ensures valves from different manufacturers can fit together properly in a system.

Furthermore, ASME B16.40 is another critical standard. It governs the design, testing, and markings for thermoplastics valves. A valve meeting this standard has undergone pressure testing and carries a clear pressure rating mark.

Standards for Safety and Fluid Contact

Finally, safety standards protect people and processes. If the valve carries water or other fluids, it must not contaminate them. The NSF/ANSI 61 certification is often required. Essentially, it proves the valve materials do not leach harmful chemicals into the water above allowed limits.

Here is a table summarizing the core standards:

| Standard | Focus Area | Why It Matters for Your Valve |

|---|---|---|

| ASTM D1784 | Material Quality | Ensures the PVC plastic has the correct strength, durability, and heat resistance for industrial use. |

| ISO 161 | Dimensions & Compatibility | Makes sure the valve will connect perfectly to other standardized pipes and fittings in your system. |

| ASME B16.40 | Valve Design & Testing | Confirms the valve is designed and built to safely handle its stated pressure ratings. |

| NSF/ANSI 61 | Drinking Water Safety | Certifies the valve is safe for use in potable water systems, with no harmful chemical leaching. |

In summary, a reputable industrial PVC valve will list these standards in its documentation. Therefore, you should always ask for this information. If a supplier cannot provide it, the valve likely does not meet industrial requirements.

How Do Pressure and Temperature Ratings of PVC Pump Valves Meet Industrial Requirements?

Choosing the wrong rating is a common and costly mistake. I always stress that the rating on the valve must exceed your system’s maximum operating point.

PVC pump valves meet industrial requirements through clear pressure (PSI/Bar) and temperature (°F/°C) ratings stamped on the valve body. Specifically, industrial-grade PVC valves are rated for higher pressures (e.g., 150 PSI) and a wider temperature range than standard valves. This ensures they withstand the stresses found in processes like water treatment or chemical transfer.

The Critical Link Between Pressure and Temperature

The pressure a PVC valve can handle is directly tied to the temperature of the fluid inside it. As temperature increases, the strength of the PVC decreases. Therefore, a valve’s pressure rating is always given at a specific temperature, usually 73°F (23°C).

For example, a valve might be rated for 150 PSI at 73°F. This is its maximum working pressure under normal conditions. However, if the fluid is heated to 140°F (60°C), the same valve’s pressure rating might drop to 75 PSI. Consequently, using the valve at 150 PSI with hot fluid would be dangerous and likely cause failure.

Typical Industrial Ratings

Industrial systems often involve varying pressures and temperatures. For this reason, high-quality industrial PVC valves are designed for this challenge.

- Pressure Ratings: Common industrial pressure ratings include 150 PSI and 200 PSI (at 73°F). Therefore, you must select a valve whose pressure rating is higher than any possible pressure surge in your system, not just the normal operating pressure.

- Temperature Range: Typically, a good industrial PVC valve can handle fluids from 0°F up to 140°F (-18°C to 60°C). For applications involving hotter fluids, you need alternative materials like CPVC or metal.

A Practical Guide for Selection

To ensure the valve meets your industrial requirements, follow these steps:

- Identify Maximum Operating Temperature: First, determine the hottest temperature the fluid will reach.

- Identify Maximum Operating Pressure: Next, find the highest pressure the valve will experience at that temperature. Remember to include potential pressure spikes from pumps.

- Check the Manufacturer’s Chart: Finally, consult the manufacturer’s pressure/temperature derating chart. Find your maximum temperature on the chart to see the corresponding maximum safe pressure.

Example Selection Table:

| Your System’s Requirement | Minimum Valve Specification Needed |

|---|---|

| Constant operation at 100°F, 80 PSI | Valve rated for at least 100 PSI at 100°F (Check the derating chart). |

| Cold water line with 100 PSI + occasional 120 PSI surges | Valve rated for at least 150 PSI at 73°F to handle the surge safely. |

| Chemical transfer at 70°F, 60 PSI | Valve rated for at least 100 PSI at 73°F, and confirmed chemically resistant to the fluid. |

By understanding and applying these ratings, you ensure the PVC valve is robust enough for your specific industrial application. This practice prevents premature failure and safety hazards.

Which Certifications Confirm PVC Pump Valve Compliance with International Industrial Standards?

Certificates are the proof of compliance. I advise clients to never accept a valve without seeing the relevant certification documents.

**Third-party certifications from independent laboratories provide the strongest confirmation. For example, look for the **NSF/ANSI 61 mark for potable water, the **UL Listing mark for electrical components in actuated valves, and the *CE marking for products sold in the European Economic Area. Essentially, these certifications verify that the product has undergone testing and meets the declared standards.*

The Role of Third-Party Certification

A manufacturer can claim their product meets a standard, but a certification from an independent lab provides trusted proof. These labs test samples from production batches to ensure consistent quality.

Key Global Certifications Explained

Different markets and applications require different certifications. Here are the most important ones:

- NSF/ANSI 61: This is the global benchmark for health and safety of products contacting drinking water. An NSF mark means a scientific organization has tested the valve. Specifically, they confirmed it does not leach contaminants above strict safety levels. This is non-negotiable for food, beverage, and water treatment plants.

- UL Listing: Underwriters Laboratories is a major global safety organization. For PVC valves, a UL Listing is often required if the valve has an electrical actuator. The UL mark certifies the electrical components are safe from fire and shock risks.

- CE Marking: This is a mandatory conformity mark for products sold within the European Economic Area. It is the manufacturer’s declaration that the product meets all applicable EU health, safety, and environmental regulations. Therefore, it is crucial for exporting to European markets.

- ISO 9001: While not a product certificate, this is a Quality Management System certification. A factory with ISO 9001 certification has proven processes to ensure consistent product quality and continuous improvement. As a result, it adds a layer of trust in the manufacturer.

How to Verify and Use Certifications

Simply seeing a logo is not enough. You should be able to request a copy of the official certification report or test summary from the supplier. This document will list the exact standards tested and the product models covered.

Certification Reference Table:

| Certification Mark | Issuing Body | What It Confirms | Critical For… |

|---|---|---|---|

| NSF/ANSI 61 | NSF International | Safety for drinking water contact; no harmful leaching. | Water treatment, food & beverage, pharmaceutical. |

| UL Listed | Underwriters Laboratories | Safety of electrical components in actuated valves. | Automated industrial systems, plant safety compliance. |

| CE Mark | Manufacturer Declaration (per EU law) | Compliance with EU Health, Safety & Environmental rules. | Selling or using products in the European market. |

| ISO 9001 | Various Certification Bodies | The factory has a certified quality management system. | Assurance of consistent manufacturing quality. |

Always specify the required certifications in your purchase order. This formalizes the requirement and gives you a basis for rejection if non-compliant products arrive. For global projects, IFAN provides valves with the full spectrum of certifications needed for international acceptance.

What Are the Consequences of Using Non-Compliant PVC Pump Valves in Industrial Systems?

The upfront savings from a cheap, non-compliant valve disappear with the first failure. In reality, the total cost is always much higher.

Using non-compliant valves leads directly to system failure, safety hazards, and financial loss. Consequences include leaks and ruptures from inadequate pressure ratings, chemical corrosion and contamination from substandard materials, and complete project rejection for lacking required certifications. Ultimately, this leads to costly delays and replacements.

Immediate Physical Failures

The most direct consequence is the valve breaking during operation. A non-compliant valve likely uses weaker materials or flawed manufacturing.

- Leaks and Bursts: If the valve body or its seals cannot handle the system pressure, it will leak or even burst open. Consequently, this causes immediate fluid loss, creates a slip hazard, damages nearby equipment, and shuts down your process line.

- Chemical Incompatibility: Industrial-grade PVC is formulated to resist a range of chemicals. In contrast, a non-compliant valve might use generic PVC that degrades, cracks, or becomes brittle when exposed to certain chemicals. This leads to sudden failure and the release of hazardous materials.

Long-Term Operational and Safety Risks

Even if it doesn’t fail immediately, a non-compliant valve creates ongoing problems.

- Contamination: Without certifications like NSF/ANSI 61, there is no guarantee the valve materials are safe. Harmful chemicals could leach from the valve into your product stream. For example, in a food or pharmaceutical plant, this would mean an entire batch is contaminated and must be destroyed.

- Inconsistent Performance: Valves that don’t meet dimensional standards may not seal correctly or may be difficult to install. As a result, this leads to chronic leaks and increased maintenance labor.

- Safety Hazards: A failed valve can release hot, pressurized, or dangerous fluids. Therefore, this poses serious risks of burns, chemical exposure, or environmental spills to workers.

Financial and Legal Repercussions

The costs of failure go far beyond replacing a single cheap valve.

- Production Downtime: First, a line shutdown for emergency repair costs thousands per hour in lost production.

- Damage Costs: Next, leaking fluids can ruin expensive motors, electronics, or finished products.

- Certification Rejection: If an inspector finds an uncertified valve in a system requiring certification, they can reject the entire installation. Consequently, you will bear the cost of removing and replacing all non-compliant parts.

- Liability: Finally, if a valve failure causes injury or environmental damage, your company faces significant legal liability and reputational harm.

Cost Comparison: Compliant vs. Non-Compliant Valve

| Cost Factor | Certified, Compliant Valve | Non-Compliant, “Cheap” Valve |

|---|---|---|

| Initial Purchase Price | Higher | Very Low |

| Risk of Failure | Very Low | Very High |

| Maintenance & Repair Cost | Low | Very High |

| Risk of Downtime | Low | Very High |

| Risk of Rejection/Fines | None | Very High |

| Total Project Cost & Risk | Predictable and Low | Unpredictable and Very High |

Choosing a compliant valve is an investment in system reliability, safety, and total cost control. Clearly, it is never worth the risk.

Conclusion

Using industrial-standard PVC pump valves is essential for safety, reliability, and cost control. For guaranteed compliant valves with full certifications, choose IFAN’s range of industrial PVC solutions.

Recent Comments