I once dealt with a commercial kitchen drain that constantly clogged at a sharp junction. Switching to a specific fitting—the Double Y Tee—solved the problem for good. It taught me that the right fitting is crucial for system performance.

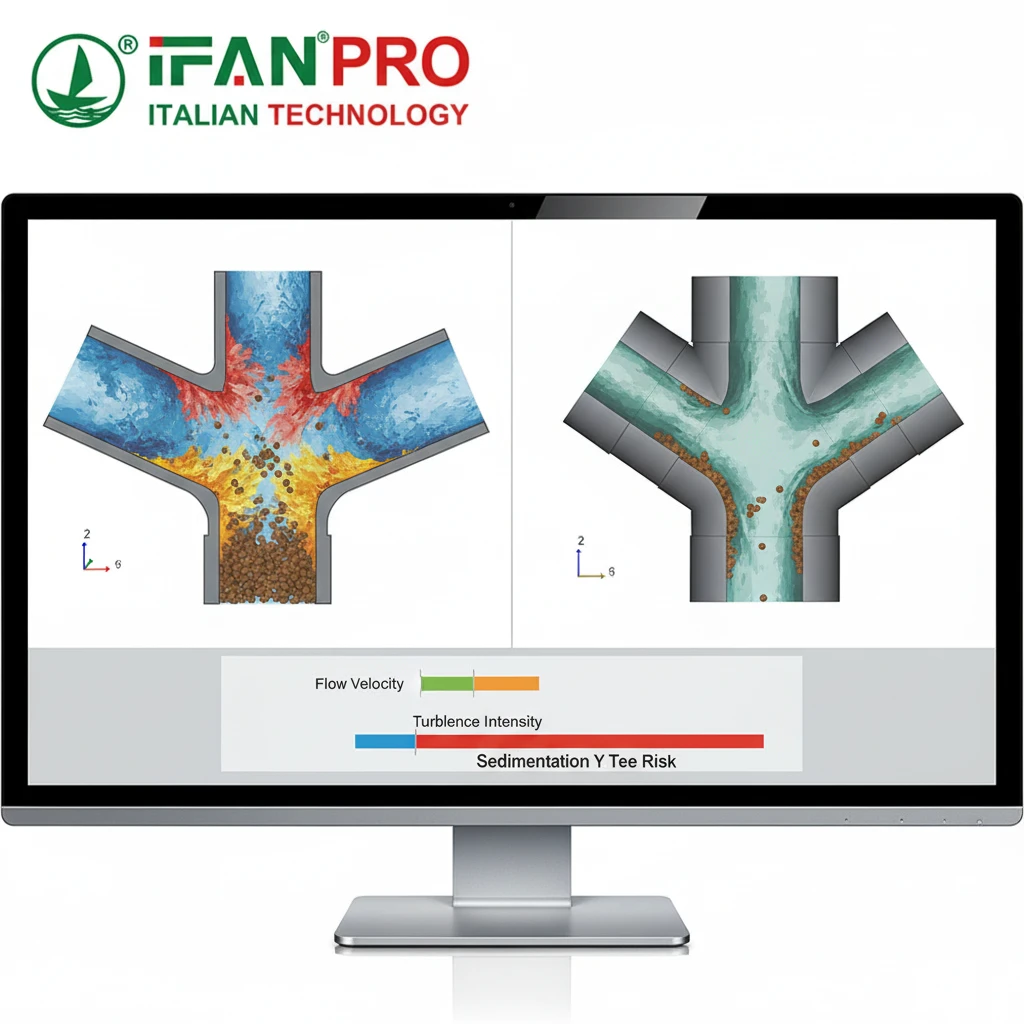

A Double Y Tee improves drainage performance by using two gradual 45-degree branch connections to merge or split flow. This smooth, angled design significantly reduces flow resistance and turbulence compared to sharp-angled fittings, preventing clogs, minimizing noise, and allowing waste to move through the system more efficiently and reliably.

If you’re tired of dealing with slow drains or frequent blockages, understanding this fitting can be a game-changer. So, let’s break down exactly how and why it works so well.

How Does a DOUBLE Y TEE Enhance Flow Efficiency in Drainage Systems?

Clogs often start at poorly designed junctions. However, the Double Y Tee is engineered to solve this exact issue.

A Double Y Tee enhances flow efficiency by utilizing a long, sweeping “Y” shape with 45-degree angles. This gentle slope drastically reduces hydraulic resistance and turbulence where flows meet, allowing water and solids to merge smoothly without slowing down or creating debris-catching eddies, which keeps the system flowing freely.

The Problem with Sharp Turns

To understand why the Double Y Tee is better, we first need to see the problem with traditional fittings like a standard Sanitary Tee. A Sanitary Tee has a 90-degree branch connection. Specifically, when wastewater from a branch line hits this 90-degree turn to join the main flow, it slams into the opposite wall of the main pipe. As a result, this sudden change in direction causes three major issues:

- Turbulence: The water flow becomes chaotic and swirling.

- Energy Loss: The force of the flow is lost as it crashes, slowing everything down.

- Clog Point: Solid waste (like food scraps or hair) can easily get trapped at this impact point, starting a buildup that leads to a full clog.

The Smooth Solution: 45-Degree Design

Next, consider how the Double Y Tee fixes this. Essentially, it replaces the sharp 90-degree turn with two gradual 45-degree bends—shaped like a long, continuous “Y”. Therefore, think of it as turning a sharp, dangerous street corner into a gentle, curved highway on-ramp.

As a result, this design has a direct impact on physics:

- Reduced Friction: Water and solids follow a much more natural path. In other words, there’s no violent collision.

- Laminar Flow: The flow remains smoother (more “laminar”), which is the most efficient way for fluids to move.

- Self-Cleaning: The smooth, fast flow has a better scouring action, helping to carry solids through the junction instead of letting them drop out.

Flow Efficiency Comparison

| Fitting Type | Branch Angle | Flow Characteristic | Clog Risk at Junction | Typical Use Case |

|---|---|---|---|---|

| Sanitary Tee | 90 degrees | High turbulence, major direction change | Very High | Vertical-to-horizontal waste connections (where flow drops vertically). |

| Single Wye (Y) | 45 degrees | Moderate turbulence, smoother merge | Low | Combining two drainage lines on a horizontal plane. |

| Double Y Tee | 45 degrees x2 | Very smooth, gradual merge | Very Low | Ideal for connecting two branch lines into a main drain on a horizontal plane. |

In summary, the Double Y Tee enhances efficiency by respecting the natural flow of water. Ultimately, it removes the primary internal obstacle within the pipe system, leading to fewer blockages, less maintenance, and overall better performance.

What Are the Key Applications for DOUBLE Y TEE in Waste Water Systems?

This fitting isn’t for every junction, but where it’s needed, it’s essential. Based on IFAN’s projects, its use is strategic.

The key applications for a Double Y Tee are in horizontal drainage lines where two similar-grade branch drains need to merge smoothly into a main collector. Common uses include connecting two bathroom group drains, linking double kitchen sink lines, combining laundry drains, and in complex commercial plumbing like apartment building stacks or restaurant grease waste lines.

Residential Plumbing Applications

In homes, the Double Y Tee is a problem-solver for specific layouts. For example, in back-to-back bathrooms, the sink, shower, and toilet drains from each side can be collected into a central Double Y Tee before going to the main stack. Consequently, this is cleaner and more efficient than multiple separate connections.

Furthermore, a Double Y Tee can elegantly merge the drain lines from a two-basin kitchen sink into a single trap arm. Similarly, if your washing machine drain and a nearby utility sink drain need to combine, a Double Y Tee is the correct fitting to prevent lint and debris from clogging at the junction.

Commercial and Industrial Applications

Here, the stakes are higher, and the Double Y Tee’s reliability is critical. For instance, in apartment buildings, connecting horizontal drain lines from multiple units to a central waste stack requires fittings that won’t clog. As a result, a Double Y Tee is standard practice here.

Additionally, in restaurant kitchen pre-waste lines, water from multiple prep sinks and floor drains often needs to combine before reaching the grease interceptor. Therefore, the smooth flow of a Double Y Tee helps prevent food solids from building up at this preliminary stage. Finally, in industrial facilities where process waste from two lines must be combined, the reduced turbulence of a Double Y Tee helps maintain consistent flow rates and prevents sedimentation.

Application Summary Table

| Application Scenario | Branch Sources | Why Use a Double Y Tee? |

|---|---|---|

| Residential Bathroom Group | Sink, Shower, Toilet (from 2 bathrooms) | Prevents hair and soap clogging at the merge point in a shared wall. |

| Commercial Kitchen | Multiple prep sinks, floor drains | Minimizes food solid buildup before the grease trap; crucial for hygiene. |

| Apartment Building | Drain lines from adjacent units | Reduces clog risk in shared walls, preventing costly repairs and tenant complaints. |

| Laundry Room | Washing machine & utility sink | Helps guide lint away from the junction, maintaining free flow. |

In conclusion, choosing the right application is key. Specifically, you would not use it for a vertical-to-horizontal change. Its specialty is horizontal-to-horizontal combinations, making it a foundational fitting for efficient, code-compliant drainage layouts.

Why Choose a DOUBLE Y TEE Over Traditional Sanitary Tee Fittings?

Many builders use sanitary tees out of habit. However, for horizontal drains, it’s often the wrong choice. Here’s the clear comparison.

Choose a Double Y Tee over a Sanitary Tee for any horizontal drain connection because it prevents clogs, reduces flow resistance, and meets modern plumbing code requirements for directional change. Sanitary tees are designed for vertical-to-horizontal drops and will cause performance issues and potential code violations if misused on horizontal lines.

The Fundamental Design Difference

This choice comes down to physics and plumbing code. First, each fitting has a designated purpose. For example, a Sanitary Tee (90-degree branch) is meant for when waste is falling vertically and needs to make a sharp turn to go horizontally. The reason is that the vertical drop provides enough force to push waste through the sharp turn. In other words, the flow direction is “top-down.”

On the other hand, a Double Y Tee (45-degree branch) is meant for when two flows are moving horizontally and need to merge to continue horizontally. Since there is no vertical drop to provide extra force, the merge must be smooth. Therefore, the flow direction is “side-to-side.”

Consequences of Using the Wrong Fitting

Now, let’s look at what happens if you use the wrong one. Specifically, using a sanitary tee on a horizontal drain line is a common mistake with bad results:

- Code Violation: Modern plumbing codes (like IPC and UPC) explicitly prohibit using a sanitary tee on its back (horizontal) for drainage. Basically, it’s not allowed because it doesn’t work well.

- Guaranteed Clogging: The 90-degree turn becomes a debris trap. In detail, solid waste hits the wall and stops. Over time, this creates a dam that catches more and more material until the drain is completely blocked.

- Poor Hydraulics: It creates excessive back pressure and turbulence, slowing the entire system down and potentially causing siphoning of water traps.

Direct Comparison: When to Use Which

| Feature | Double Y Tee (or Single Wye) | Sanitary Tee |

|---|---|---|

| Primary Function | To combine horizontal drain lines. | To change flow from vertical to horizontal. |

| Branch Angle | 45 degrees | 90 degrees |

| Flow Efficiency | Excellent for horizontal merges. | Poor for horizontal merges; causes turbulence. |

| Clog Risk | Very Low at the fitting. | Very High if used horizontally. |

| Plumbing Code | Required for horizontal-to-horizontal connections. | Prohibited for horizontal-to-horizontal connections. |

| Best For | Connecting two sinks, bathroom groups, any horizontal merge. | Connecting a vertical sink drain to a horizontal line. |

In short, it’s not a matter of one being “better” in all cases. Instead, it’s about using the right tool for the job. For merging horizontal drains, the Double Y Tee is the right tool, and the sanitary tee is the wrong—and often illegal—tool. Ultimately, choosing correctly saves money on future maintenance and ensures a reliable, code-compliant system.

How to Install a DOUBLE Y TEE for Optimal Drainage System Performance?

Even the best fitting can fail if installed incorrectly. However, proper installation ensures you get all the performance benefits.

To install a Double Y Tee for optimal performance, ensure it is placed on a horizontal plane with the correct slope, oriented so the flow direction matches the main drain, and securely supported. Always use the proper primer and solvent cement for your pipe material (like PVC or ABS), and allow for a full cure time before testing the system.

Step 1: Planning and Preparation

A correct installation is straightforward if you follow these steps. First, gather your tools: a pipe cutter, deburring tool, measuring tape, level, PVC/ABS primer, and solvent cement. Then, before any glue, plan the layout. Remember, the Double Y Tee must be installed horizontally. Specifically, the main outlet should point in the direction of the main drain flow. Meanwhile, the two branch inlets should face the sources. After that, hold the pipes and fitting together in a “dry fit” to measure and mark the exact insertion depth on each pipe.

Step 2: Cutting and Preparing Pipes

Next, cut the pipes to length using a proper pipe cutter for a clean, square edge. The reason is that a ragged cut can cause an uneven glue joint and create an internal lip that catches debris. After cutting, use a deburring tool or sandpaper to remove any plastic burrs from the inside and outside of the pipe ends. This step is important because a burr on the inside creates a ridge that disrupts smooth flow.

Step 3: Solvent Welding (Gluing)

This is the most critical step for a leak-proof, strong joint. Follow this sequence carefully:

- Apply Purple Primer: First, apply PVC primer (it’s usually purple) to the outside of the pipe end and the inside of the Double Y Tee socket. This cleans and softens the plastic for a strong bond. Then, let it dry for a few seconds.

- Apply Solvent Cement: Next, apply a thin, even layer of clear PVC solvent cement over the primed areas on both the pipe and the fitting.

- Assemble Immediately: Quickly push the pipe into the fitting, giving it a quarter turn as you insert it. This spreads the glue evenly. Then, hold it firmly in place for about 15-30 seconds to prevent it from pushing back out.

- Check Orientation: Ensure the fitting is correctly aligned before the glue sets (you have only a few seconds). For example, use your level to check it’s horizontal.

Step 4: Support, Slope, and Cure

Once installed, the entire pipe run must be properly supported with pipe hangers or straps. More importantly, it must have a consistent downward slope (or “fall”) toward the main sewer line. Specifically, the standard slope is 1/4 inch of drop per linear foot of pipe (2% slope). This slope uses gravity to maintain water velocity and carry solids away. Finally, you must allow the joints to fully cure. So, follow the glue manufacturer’s instructions, which usually recommend 2 to 24 hours before putting pressure on the system.

Common Installation Mistakes to Avoid

| Mistake | Consequence | How to Avoid |

|---|---|---|

| Installing it vertically. | Defeats its purpose; can cause improper drainage. | Always check with a level during dry fit and gluing. |

| Incorrect flow direction. | Waste flows into a dead end, causing immediate clog. | Double-check that the main outlet points downstream. |

| Using too little or too much cement. | Weak joint (leak) or excess glue inside pipe (clog). | Apply a thin, even coat; a small bead around the pipe is enough. |

| Not allowing proper cure time. | Joints can separate under pressure. | Follow glue manufacturer’s instructions (usually 2-24 hours). |

| Ignoring proper slope. | Water and waste sit in the pipe, causing clogs and smells. | Measure and mark slope lines before installing supports. |

Following these steps ensures your Double Y Tee performs as designed. In the end, it will provide a smooth, reliable, and clog-free merge point for your drainage system for years to come.

Conclusion

The Double Y Tee is a smart, code-required solution for efficient horizontal drainage. For reliable, high-quality DOUBLE Y TEE fittings, trust IFAN to supply the right components for your project.

Recent Comments