I recently visited a factory where corroded metal air lines were contaminating their entire production line. This frustrating experience showed me why more industries are switching to PPR for compressed air systems.

PPR pipes are excellent for compressed air systems because they handle pressures up to 20 bar at 20°C, resist corrosion completely, and prevent rust contamination. Their smooth interior reduces pressure drops, and fused joints eliminate leaks, making them more reliable and cost-effective than metal alternatives for most industrial applications.

Let me explain why PPR is becoming the preferred choice for compressed air installations and how it solves common problems in these systems.

What are the pressure ratings for PPR pipes in compressed air systems?

Many factory managers worry about pipe bursts. I’ve seen PPR systems handle pressure spikes that would damage metal pipes.

PPR pipes for compressed air typically handle working pressures of 10-16 bar at 20°C, with higher pressure ratings available. The pressure capacity depends on pipe wall thickness (SDR rating) and operating temperature. Unlike metal pipes, PPR maintains its strength while being lightweight and easier to install.

Understanding Pressure Ratings

When selecting PPR pipes for compressed air, the pressure rating is the most critical factor. PPR pipes are classified by their Standard Dimension Ratio (SDR), which determines their pressure capacity. Thicker walls (lower SDR numbers) handle higher pressures.

The temperature of your compressed air significantly affects pressure ratings. As air temperature increases, the pressure rating decreases. For example, a PPR pipe rated for 16 bar at 20°C might only be rated for 12 bar at 40°C. Always consider both your operating pressure and temperature when selecting pipes.

Pressure Comparison Across Materials

Different pipe materials offer varying pressure capacities. This table shows how PPR compares to traditional options:

| Material | Typical Pressure Rating at 20°C | Temperature Sensitivity | Pressure Drop Characteristics |

|---|---|---|---|

| PPR | 10-16 bar | Moderate decrease with temperature | Low friction loss |

| Galvanized Steel | 15-20 bar | Minimal change | High friction loss |

| Copper | 20-25 bar | Minimal change | Medium friction loss |

| PVC | 8-12 bar | Significant decrease | Low friction loss |

Safety Factors and Installation Impact

PPR systems include a significant safety margin beyond their rated working pressure. Most quality PPR pipes can withstand pressure surges up to 50% above their rated capacity without damage. The heat-fused joint system is particularly valuable here because, unlike threaded connections that can weaken under vibration and pressure cycling, fused joints maintain their integrity.

For compressed air applications, I recommend using PPR pipes with SDR 6 or SDR 7.4 ratings, which provide the best balance of pressure handling and cost-effectiveness for most industrial applications between 8-12 bar operating pressure.

Why is PPR corrosion-resistant ideal for compressed air applications?

I’ve seen too many metal air lines fail from internal corrosion. The factory manager showed me rusty water pouring from their air line drains – a problem PPR completely eliminates.

PPR’s corrosion resistance is ideal for compressed air because it prevents rust contamination in tools and equipment, eliminates pipe wall thinning over time, and maintains air quality. Unlike metal pipes, PPR won’t corrode from moisture in compressed air, ensuring clean, dry air delivery throughout the system.

The Moisture Problem in Compressed Air

All compressed air contains some moisture, which is the primary cause of corrosion in metal piping systems. When humid air is compressed, water vapor condenses inside the pipes. This moisture attacks metal pipes from the inside, creating rust that contaminates the air supply.

PPR pipes are completely inert to water and moisture. They don’t rust, corrode, or degrade when exposed to wet compressed air. This means the air reaching your tools and equipment remains free of rust particles that can damage sensitive instruments and manufacturing equipment.

Impact on Air Quality and Equipment

The corrosion resistance of PPR provides multiple benefits for compressed air quality:

- Cleaner Air Output: No rust particles means cleaner air for painting, sandblasting, and instrument air applications

- Protected Equipment: Tools, valves, and cylinders last longer without abrasive rust particles

- Consistent Performance: Pipe internal diameter remains unchanged, maintaining stable pressure

- No Chemical Treatment Needed: Unlike some metal systems, you don’t need chemical corrosion inhibitors

Maintenance Cost Comparison

The corrosion resistance directly translates to maintenance savings:

| Maintenance Issue | Metal Pipes | PPR Pipes |

|---|---|---|

| Pipe Replacement Due to Corrosion | Every 5-10 years | Never needed |

| Filter Changes Due to Contamination | Frequent | Reduced frequency |

| Equipment Damage from Rust | Common | Rare |

| System Flushing and Cleaning | Regular required | Minimal needed |

Long-Term Reliability

Since PPR doesn’t corrode, the pipe wall thickness remains constant throughout its lifespan. Metal pipes gradually thin from internal corrosion, weakening over time and potentially leading to catastrophic failures. With PPR, the 50-year lifespan estimate is realistic because the material doesn’t degrade from moisture exposure.

Which certifications ensure PPR fittings meet compressed air standards?

A client nearly bought uncertified PPR pipes last month. The missing pressure rating markings would have caused serious safety issues in their air system.

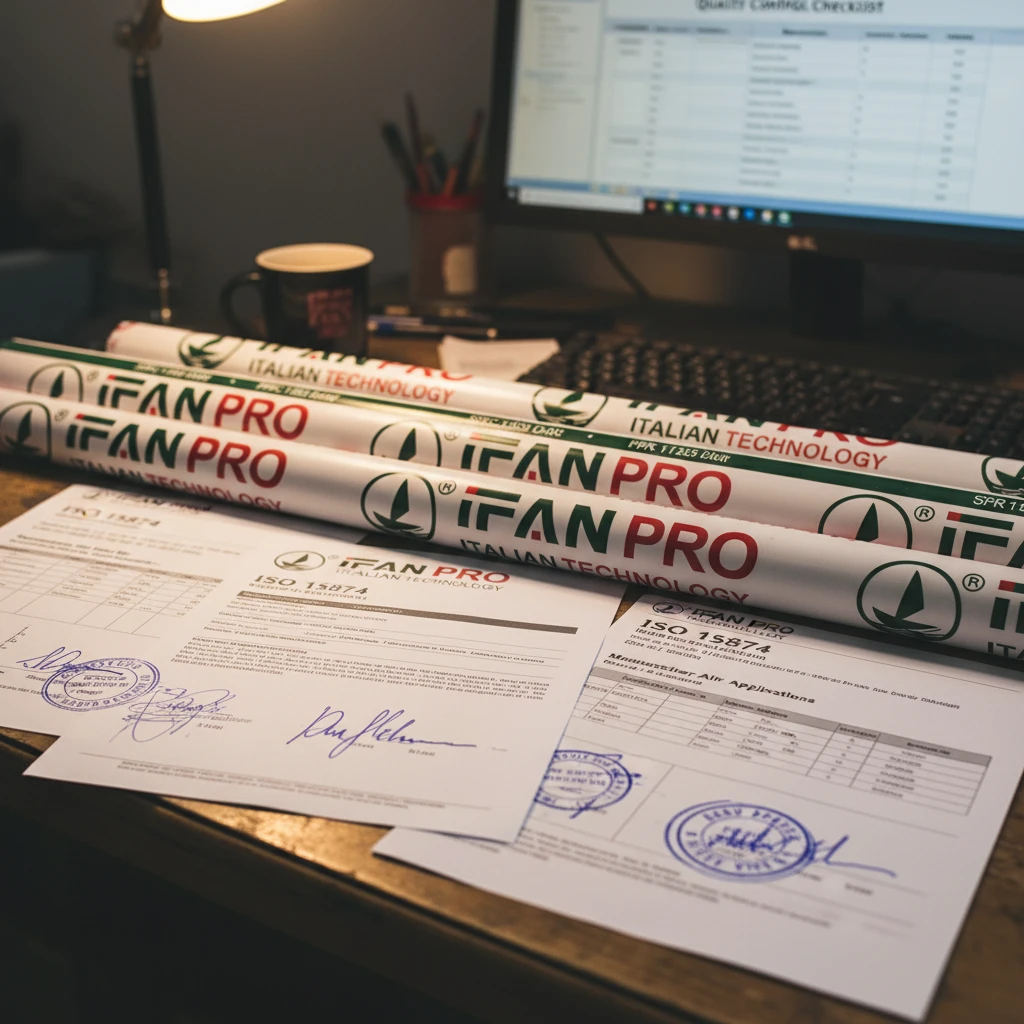

PPR fittings for compressed air should have ISO 15874 certification for hot and cold water systems (which covers pressure requirements), and manufacturers’ explicit approval for compressed air service. Look for DIN 8077/8078 standards for material quality, and ensure products carry CE marking with pressure rating documentation for your specific application.

Understanding Certification Hierarchy

Certifications ensure that PPR products meet minimum quality and safety standards. For compressed air applications, no single certification specifically covers PPR for air systems, so we rely on a combination of general PPR certifications and manufacturer testing.

The ISO 15874 standard is crucial because it certifies that PPR pipes and fittings meet requirements for pressurized systems. While originally designed for water systems, the pressure and temperature ratings directly translate to compressed air applications when the manufacturer approves such use.

Key Certifications to Verify

Always check for these certifications when selecting PPR for compressed air:

| Certification | What It Covers | Importance for Compressed Air |

|---|---|---|

| ISO 15874 | Polypropylene piping systems | Validates pressure rating claims |

| DIN 8077/8078 | PP pipe dimensions and quality | Ensures dimensional accuracy |

| CE Marking | European conformity | Confirms general product safety |

| NSF/ANSI 61 | Drinking water system components | Indicates material safety |

Manufacturer Documentation Requirements

Beyond standard certifications, require manufacturers to provide:

- Written confirmation that products are suitable for compressed air service

- Pressure rating tables specific to air applications

- Temperature de-rating guidelines for compressed air

- Installation instructions for compressed air systems

Quality Verification Steps

When auditing potential PPR suppliers for compressed air applications:

First, verify that all products have permanent markings showing material type, pressure rating, size, and manufacturer. Reject any unmarked products immediately.

Second, require test reports from independent laboratories showing pressure cycling performance. Compressed air systems experience constant pressure cycles that can fatigue materials, so cycling performance is more important than for water systems.

Third, check that fittings and pipes come from the same certification batch. Mixing materials from different production batches can lead to fusion problems.

How does PPR reduce maintenance costs in compressed air installations?

A manufacturing plant reduced their air system maintenance by 80% after switching to PPR. Their maintenance supervisor told me the savings paid for the new system in under two years.

PPR reduces maintenance costs by eliminating corrosion-related repairs, minimizing leakage through fused joints, reducing filter replacement frequency, and preventing pressure drops that increase energy consumption. The system requires no internal cleaning, doesn’t need protective coatings, and maintains consistent performance for decades without degradation.

Leakage Reduction Benefits

Compressed air systems in industrial settings typically lose 20-30% of their air through leaks. PPR’s fused joint system virtually eliminates leakage points. Unlike threaded connections that loosen over time, heat-fused joints become monolithic sections that cannot leak.

The leakage reduction provides immediate cost savings through:

- Lower compressor energy consumption

- Reduced compressor runtime and maintenance

- Smaller compressor capacity requirements

- Consistent pressure at point of use

Maintenance Activity Comparison

Here’s how maintenance requirements differ between traditional metal and PPR systems:

| Maintenance Activity | Metal Piping | PPR Piping |

|---|---|---|

| Leak Inspection and Repair | Monthly | Annual visual check |

| Pipe Replacement Due to Corrosion | Every 5-10 years | Never |

| System Draining and Cleaning | Quarterly | Not required |

| Joint Re-tightening | Annual | Never |

| Filter Element Changes | Monthly | Quarterly |

Energy Efficiency Advantages

PPR’s smooth interior surface reduces friction loss, meaning lower pressure drops across the system. This allows you to run your compressor at lower pressure settings while maintaining required pressure at point of use. For every 1 bar reduction in compressor pressure, you save approximately 7% in energy costs.

The non-corroding surface maintains this efficiency advantage throughout the system’s life. Metal pipes become progressively rougher from internal corrosion, increasing pressure drop and energy costs over time.

Long-Term Cost Analysis

While PPR has similar initial costs to quality metal systems, the maintenance savings create significant long-term advantages:

- Year 1-5: 60% lower maintenance costs

- Year 6-10: 80% lower maintenance costs (metal systems need corrosion repairs)

- Year 11-20: 90% lower maintenance costs (metal systems often require complete replacement)

- Year 21+: PPR continues with minimal maintenance while metal systems incur major replacement costs

The total cost of ownership over 20 years typically shows PPR systems costing 40-60% less than metal alternatives when factoring in maintenance, energy savings, and system longevity.

Conclusion

PPR offers reliable, cost-effective performance for compressed air systems with superior corrosion resistance and lower maintenance. For certified PPR pipes and fittings designed for compressed air applications, choose IFAN’s industrial-grade PPR products for your next installation.

Recent Comments