I’ve seen too many hot water systems fail due to corrosion and scaling. That’s why I now recommend CPVC for all hot water applications.

CPVC is the ideal choice for hot water lines because it withstands high temperatures up to 200°F (93°C), resists chlorine degradation, prevents scale buildup, and costs significantly less than metal alternatives. Its solvent cement joints create permanent, leak-free connections that maintain integrity under thermal stress.

Now let’s explore why CPVC stands out for hot water distribution systems.

What Temperature Resistance Makes CPVC Ideal for Hot Water Systems?

Hot water can destroy ordinary plastics. I’ve witnessed PVC pipes deform under continuous heat exposure, but CPVC performs differently.

CPVC maintains structural integrity at temperatures up to 200°F (93°C), making it perfect for residential and commercial hot water systems. Unlike standard PVC which softens at 140°F (60°C), CPVC’s chlorinated molecular structure provides superior heat resistance that prevents deformation and maintains pressure ratings under thermal stress.

Understanding Thermal Performance

CPVC’s exceptional temperature resistance comes from its chemically enhanced structure. The additional chlorine atoms in CPVC’s molecular backbone create stronger bonds that require more energy to break. This means CPVC pipes won’t soften, warp, or lose their shape when exposed to continuous high temperatures.

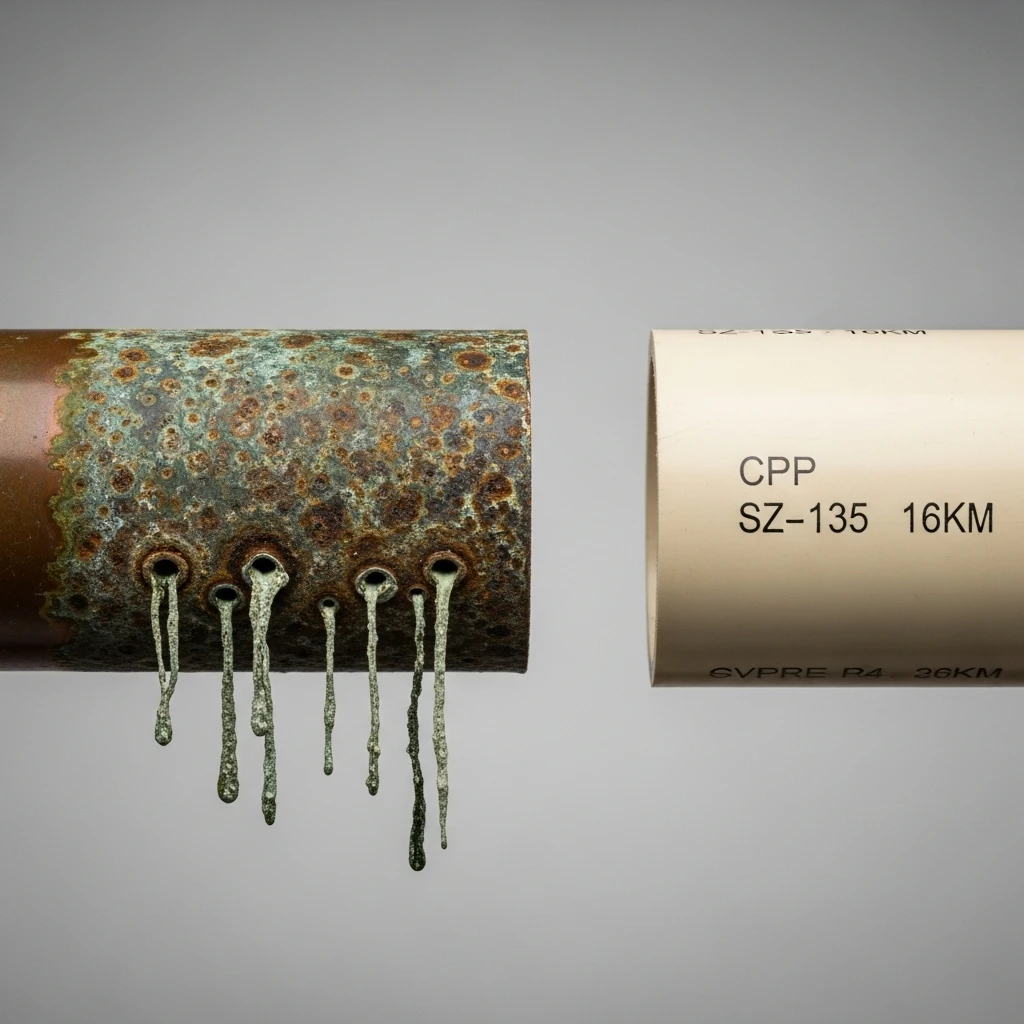

Traditional metal pipes face different challenges with hot water. While metals don’t melt at water heater temperatures, they corrode faster when exposed to hot, oxygenated water. Copper pipes particularly suffer from pitting corrosion in hot water systems, leading to pinhole leaks over time.

Temperature Comparison Guide

This table shows how different materials handle hot water temperatures:

| Material | Maximum Continuous Temperature | Key Limitations |

|---|---|---|

| CPVC | 200°F (93°C) | Excellent long-term performance |

| Copper | 250°F (121°C) | Prone to corrosion in hot water |

| PEX | 180°F (82°C) | Requires oxygen barrier for hot water |

| PVC | 140°F (60°C) | Not suitable for hot water |

| Galvanized Steel | 200°F (93°C) | Rapid corrosion in hot water |

Real-World Performance

In practice, most residential hot water systems operate between 120°F and 140°F. CPVC provides a substantial safety margin above these temperatures. Even during water heater malfunctions where temperatures might spike temporarily, CPVC maintains its structural integrity.

The material’s thermal expansion characteristics also make it practical for real installations. CPVC expands at a predictable rate of approximately 0.000034 inches per inch per degree Fahrenheit. This means installers can easily calculate and accommodate expansion in long runs, preventing stress on the system.

How Does CPVC’s Chlorine Resistance Benefit Hot Water Pipe Durability?

Municipal water treatment uses chlorine, and hot water accelerates its corrosive effects. I’ve replaced many copper pipes eaten away by chlorinated water.

CPVC’s exceptional chlorine resistance comes from its chlorinated molecular structure, which makes it inert to the oxidizing effects of chlorine and chloramines in water supplies. This prevents the material degradation, cracking, and failure that commonly affect metal pipes in chlorinated water systems.

The Chlorine Challenge

Most municipal water systems maintain residual chlorine levels between 1.0-4.0 ppm to control bacterial growth. While this protects public health, it creates a harsh environment for plumbing materials. Hot water accelerates chemical reactions, making chlorine even more aggressive toward metal pipes.

Copper pipes are particularly vulnerable to chlorinated water. The combination of chlorine, heat, and water creates ideal conditions for Type I pitting corrosion. This localized corrosion leads to pinhole leaks that can cause significant property damage before detection.

Material Durability Comparison

CPVC’s resistance to chlorine degradation ensures long-term reliability:

| Material | Chlorine Resistance | Failure Mechanism |

|---|---|---|

| CPVC | Excellent | No chlorine-related degradation |

| Copper | Poor | Pitting corrosion and pinhole leaks |

| PEX | Good | Potential slow oxidation over decades |

| Galvanized Steel | Very Poor | Rapid corrosion and scale buildup |

Long-Term Performance Evidence

Extensive testing and decades of field experience demonstrate CPVC’s immunity to chlorine-induced failure. Unlike metals that corrode from both inside and outside, CPVC maintains consistent wall thickness throughout its service life. This means the pipe that’s installed today will have the same pressure-bearing capacity decades later.

The smooth interior surface of CPVC provides additional benefits. It prevents scale accumulation that often plagues metal pipes in hard water areas. Mineral deposits not only reduce flow but also create isolated environments where chlorine concentrations can become even more concentrated, accelerating metal corrosion.

Why is CPVC More Cost-Effective Than Metal Pipes for Hot Water Lines?

Budget-conscious clients always appreciate CPVC. I’ve helped projects stay on budget by switching from copper to CPVC systems.

CPVC costs 30-50% less than copper for equivalent hot water systems when considering both material and installation expenses. Its corrosion resistance eliminates replacement costs, its insulation properties reduce heat loss, and its lightweight nature cuts labor time and costs significantly.

Initial Cost Analysis

The raw material cost for CPVC pipes and fittings is substantially lower than copper. More importantly, installation requires less specialized labor and fewer tools. A two-person crew can install CPVC plumbing much faster than equivalent metal systems, resulting in lower labor costs.

The weight difference alone creates significant savings. CPVC weighs about 1/6th as much as copper, making it easier to handle, transport, and install. Workers can carry longer sections without assistance, and supporting requirements are minimal compared to heavy metal pipes.

Long-Term Savings Breakdown

The real financial benefits emerge over the system’s lifespan:

- Zero Corrosion Costs: CPVC won’t corrode, eliminating the primary cause of plumbing failures in hot water systems

- Reduced Heat Loss: CPVC’s low thermal conductivity means hot water stays hotter longer, reducing energy costs

- Minimal Maintenance: No scaling means consistent water pressure and flow rates over decades

- No Re-piping: Unlike metals, CPVC maintains full wall thickness throughout its service life

Total Cost Comparison

This 20-year cost analysis demonstrates CPVC’s advantage:

| Cost Category | CPVC System | Copper System |

|---|---|---|

| Material Costs | $2,500 | $4,800 |

| Installation Labor | $3,000 | $5,500 |

| Energy Loss (20 years) | $800 | $1,600 |

| Maintenance/Repairs | $300 | $2,500 |

| System Replacement | $0 | $8,000 |

| Total 20-Year Cost | $6,600 | $22,400 |

The insulation properties of CPVC contribute significantly to operational savings. Copper’s high thermal conductivity means hot water loses heat as it travels through pipes, requiring higher thermostat settings and more energy consumption. CPVC acts as a natural insulator, maintaining water temperature with less energy input.

What Installation Advantages Does CPVC Offer for Hot Water Plumbing?

Time-strapped contractors love CPVC installations. I’ve seen projects completed days ahead of schedule by using CPVC instead of metals.

CPVC installation is faster and simpler than metal systems because it uses lightweight solvent cement joints that set in minutes, requires no torches or special ventilation, and can be easily modified on-site. The one-step joining process creates permanent, leak-free connections without skilled trades or expensive equipment.

Streamlined Installation Process

CPVC installation involves four simple steps: cut, deburr, prime, and cement. The solvent welding process chemically fuses the pipe and fitting into a single homogeneous piece that’s stronger than the pipe itself. This eliminates the reliability issues associated with threaded, compressed, or crimped connections.

Unlike soldering copper, CPVC joining requires no open flames, eliminating fire risks and the need for hot work permits. There’s no smoke, fumes, or fire watch requirements, making installation safer and allowing work to continue in occupied buildings without disruption.

Installation Method Comparison

Different materials require different installation approaches:

| Installation Step | CPVC | Copper | PEX |

|---|---|---|---|

| Cutting Tool | Simple cutter | Tube cutter | PEX cutter |

| Joining Method | Solvent cement | Soldering | Crimping/Clamping |

| Special Equipment | None | Torch, gas | Crimp tools |

| Joint Setting Time | 5-10 minutes | Cool naturally | Immediate |

| Skill Level Required | Basic | Skilled trades | Moderate |

Practical Benefits for Installers

The lightweight nature of CPVC makes installation physically easier. Workers can handle 20-foot lengths without strain, reducing fatigue and increasing productivity. Measurements and cuts are more forgiving than with rigid metal pipes, and mistakes are easily corrected by simply cutting out a section and rejoining with couplings.

CPVC’s flexibility during installation is another significant advantage. While the material is rigid when installed, it has enough flexibility to accommodate slight misalignments during assembly. This forgiveness means installers spend less time making perfect measurements and more time making progress.

Weather and Site Advantages

CPVC installation isn’t weather-dependent like soldering. While extreme cold affects solvent cement setting times, installations can proceed in conditions that would halt copper soldering. Rain, wind, or cold temperatures don’t prevent CPVC installation, keeping projects on schedule.

The clean work area with CPVC installation benefits everyone. No lead-containing solders, no acidic fluxes, and no metal shavings contaminate the work area. This creates a safer environment for workers and eliminates the need for post-installation flushing to remove metal debris from the system.

Conclusion

CPVC delivers superior performance, cost savings, and installation efficiency for hot water systems. For certified CPVC pipes and fittings that meet international standards, choose IFAN for your next hot water plumbing project.

Recent Comments