In a chemical processing facility expansion project, the switch from traditional metal piping to PP-R resulted in a 40% reduction in installation time and eliminated the corrosion-related failures that had plagued the existing system. This real-world validation demonstrates why PP-R has become the material of choice for demanding industrial applications across multiple sectors.

PP-R’s suitability for industrial applications stems from its exceptional chemical resistance, robust pressure-bearing capacity at elevated temperatures, long-term reliability, and installation efficiency. These characteristics combine to deliver superior performance in industrial settings where traditional materials often fail under aggressive chemical exposure, high temperatures, and constant pressure demands.

The transition to PP-R in industrial environments represents a significant advancement in piping technology. Understanding the specific properties that make this material ideal for industrial use ensures proper application across various sectors and operating conditions.

How Does Industrial PP-R Piping Withstand High-Pressure and High-Temperature Applications?

At a manufacturing facility experiencing repeated failures with metal pipes in their high-temperature process lines, PP-R installation provided uninterrupted service for over five years without a single pressure or temperature-related failure, demonstrating remarkable stability under demanding conditions.

Industrial-grade PP-R maintains structural integrity at temperatures up to 95°C and pressures to 25 bar through its reinforced molecular structure and stabilized polymer composition. The material’s pressure-temperature relationship remains stable over decades of continuous operation, outperforming many metallic alternatives in sustained high-demand applications.

Material Strength Characteristics

PP-R’s performance under extreme conditions begins with its molecular design. The random copolymer structure provides inherent stability that resists deformation under mechanical and thermal stress. Unlike homogeneous polymers, this structure distributes stress evenly throughout the material, preventing localized failure points.

The thermal stability of industrial PP-R represents another critical advantage. The material maintains dimensional stability across a wide temperature range (-10°C to +95°C), with minimal thermal expansion compared to other plastics. This characteristic reduces stress on support systems and prevents the joint failures common in materials with higher expansion coefficients.

Pressure Performance Data

Long-term testing confirms PP-R’s capability in demanding applications:

| Operating Condition | PP-R Performance | Metal Pipe Comparison | Advantage Significance |

|---|---|---|---|

| Continuous 80°C Operation | Maintains 75% pressure rating | Requires derating to 50% | Higher safety margin |

| Thermal Cycling (20-70°C) | No fatigue failure | Stress corrosion cracking | Reduced maintenance |

| Pressure Surges (150% working pressure) | Elastic recovery | Permanent deformation | System resilience |

| 50-Year Service Life | Maintains pressure capacity | Progressive strength loss | Predictable performance |

What Chemical Resistance Properties Make PP-R Suitable for Industrial Fluid Transport?

A pharmaceutical plant eliminated three separate piping systems by implementing PP-R throughout their facility, demonstrating its compatibility with diverse chemicals from ultrapure water to aggressive cleaning solutions while maintaining fluid purity.

PP-R offers universal chemical resistance to acids, alkalis, salts, and alcohols across a broad pH range (1-14), creating exceptional suitability for industrial fluid transport. This comprehensive chemical immunity prevents the degradation, swelling, and stress cracking that limits other materials in aggressive industrial environments.

Chemical Compatibility Spectrum

The chemical resistance of PP-R stems from its non-polar polymer structure. This characteristic prevents interaction with most industrial chemicals, including strong acids, caustic solutions, and oxidizing agents. Unlike metals that corrode or other plastics that swell or degrade, PP-R maintains its structural integrity when exposed to challenging process fluids.

Industrial applications benefit particularly from PP-R’s resistance to both acidic and alkaline environments. While metals typically withstand one or the other, PP-R performs equally well across the entire pH spectrum. This versatility simplifies system design when handling multiple process streams with varying chemical characteristics.

Industrial Chemical Performance

Documented performance in specific industrial applications:

| Chemical Environment | PP-R Performance | Alternative Material Limitations | Industrial Impact |

|---|---|---|---|

| Hydrochloric Acid (20%) | No degradation | Severe metal corrosion | Elimination of lining systems |

| Sodium Hydroxide (50%) | Full compatibility | Aluminum and zinc attack | Unified system design |

| Chlorinated Water | No stress cracking | Brass dezincification | Reduced water treatment |

| Organic Solvents | Resistance to permeation | PVC softening | Broader chemical handling |

Which International Certifications Ensure PP-R Quality for Industrial Piping Systems?

When a multinational corporation standardized their global facilities on PP-R, the certification requirements eliminated 80% of potential suppliers, demonstrating how rigorous international standards ensure consistent quality for critical industrial applications.

Industrial PP-R quality is verified through ISO 15874 for material and performance standards, NSF/ANSI 61 for potable water safety, DIN 8077/8078 for dimensional and pressure specifications, and ASTM F2389 for pressure-rated applications. These certifications provide comprehensive verification of material consistency, performance capabilities, and long-term reliability.

Certification Requirements Analysis

Each certification addresses specific quality aspects critical to industrial applications. ISO 15874 establishes the fundamental requirements for PP-R materials, fittings, and systems, including long-term hydrostatic strength testing that predicts 50-year performance under pressure. This international standard ensures consistent quality regardless of manufacturing location.

NSF/ANSI 61 certification proves crucial for industries requiring potable water compliance, including food processing, pharmaceuticals, and beverage production. This certification verifies that materials won’t leach harmful substances into water, maintaining fluid purity in sensitive industrial processes.

Industry-Specific Certification Needs

Different industrial sectors require specialized certifications:

| Industry Sector | Critical Certifications | Quality Assurance Focus | Compliance Impact |

|---|---|---|---|

| Pharmaceutical | USP Class VI, FDA 21 CFR | Extractables and leachables | Product safety validation |

| Food & Beverage | NSF/ANSI 51, EU 10/2011 | Food contact safety | Regulatory compliance |

| Chemical Processing | ISO 15874, DIN 8077 | Chemical resistance | System reliability |

| Semiconductor | SEMI F57 | Ultra-pure water compatibility | Product yield protection |

How Does PP-R Provide Cost-Effective Solutions for Large-Scale Industrial Projects?

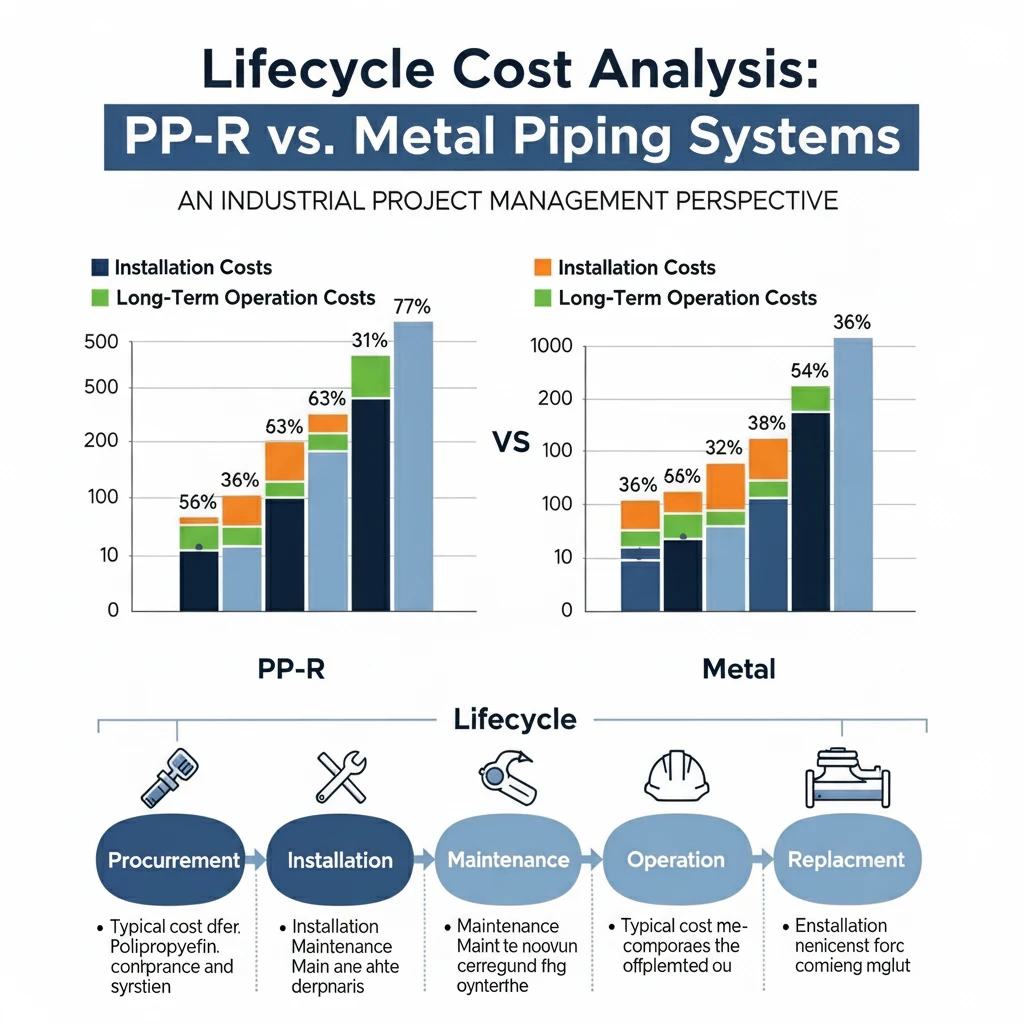

A comprehensive lifecycle cost analysis at a large industrial campus revealed that PP-R installation offered 35% lower total cost of ownership compared to metal alternatives, with savings accelerating significantly beyond the 10-year mark due to eliminated maintenance and replacement costs.

PP-R delivers cost-effectiveness through rapid installation that reduces labor requirements, eliminated maintenance from corrosion protection, energy efficiency from superior thermal properties, and long service life that minimizes replacement cycles. These factors combine to provide significantly lower total cost of ownership compared to traditional industrial piping materials.

Installation Efficiency Advantages

The installation benefits begin with PP-R’s lightweight nature, which reduces handling equipment requirements and accelerates installation rates. The heat fusion joining system creates permanent connections in minutes without specialized welding skills, compared to the hours required for welding metallic systems. This efficiency becomes particularly valuable in large-scale projects with thousands of connections.

Maintenance cost reduction represents another significant advantage. PP-R’s corrosion resistance eliminates the ongoing maintenance, monitoring, and chemical treatments required to protect metallic systems in industrial environments. The non-scaling surface maintains hydraulic efficiency without mechanical cleaning or chemical descal-ing treatments.

Lifecycle Cost Comparison

Comprehensive cost analysis demonstrates PP-R’s economic advantages:

| Cost Category | PP-R System | Metal Piping System | Cost Difference |

|---|---|---|---|

| Initial Installation | 100% (baseline) | 130-160% | 30-60% savings |

| 10-Year Maintenance | 5-8% of initial | 25-40% of initial | 70-80% reduction |

| Energy Consumption | Lower pumping costs | Higher friction losses | 15-20% savings |

| System Replacement | 50+ years | 15-25 years | 50% longer lifespan |

| Fluid Contamination | No treatment needed | Filtration required | Additional savings |

Project Scale Considerations

The economic advantages of PP-R accelerate with project scale. In large industrial installations, the material’s consistent performance across extensive piping networks eliminates the variability that often plagues metallic systems. The standardized joining system ensures consistent quality regardless of crew experience level, reducing the specialized supervision required for critical metallic welds.

Additionally, PP-R’s design flexibility enables optimization opportunities not possible with rigid metallic systems. The ability to create custom solutions with standard components reduces fabrication time and minimizes special-order items that often delay industrial projects.

Conclusion

PP-R’s ideal suitability for industrial applications stems from its proven performance under extreme conditions, universal chemical resistance, rigorous international certifications, and demonstrable cost-effectiveness throughout the project lifecycle. These characteristics combine to deliver reliable, maintenance-free performance across diverse industrial sectors while providing significant economic advantages over traditional piping materials. The comprehensive benefits position PP-R as the contemporary solution for industrial piping challenges, particularly where corrosion resistance, fluid purity, and long-term reliability are paramount considerations.

Recent Comments