Throughout my plumbing career in cold-climate regions, I’ve witnessed numerous pipe freezing incidents that taught me valuable lessons about material performance. PEX pipes have revolutionized cold-weather plumbing with their remarkable ability to withstand freeze-thaw cycles that would destroy traditional piping materials. However, understanding their limits and proper installation techniques is crucial for maximizing this inherent advantage.

PEX pipes can generally withstand freezing and thawing cycles significantly better than rigid pipes due to their flexible cross-linked polymer structure that allows expansion when water freezes. Unlike copper or CPVC pipes that typically burst under ice pressure, PEX can expand up to 300% and often return to its original shape when thawed, though this capability varies by PEX type and installation conditions.

For context on how PEX’s performance compares to traditional materials long-term, refer to our guide: PEX vs. Copper .

What material properties allow PEX to expand during freezing conditions?

PEX’s unique molecular structure provides the flexibility and memory characteristics that enable it to withstand freezing conditions far better than traditional piping materials.

PEX’s cross-linked polyethylene structure creates a molecular network that can stretch and return to its original shape, allowing the pipe to expand when water freezes and contracts when thawing occurs. This elastic memory, combined with the material’s toughness and fatigue resistance, enables PEX to survive multiple freeze-thaw cycles that would rupture rigid pipes.

The science behind PEX’s freeze resistance lies in its fundamental material properties, which differ significantly from traditional plumbing materials.

Molecular Structure Advantages

PEX’s cross-linked polymer chains form a three-dimensional network that behaves similarly to a dense collection of microscopic springs. When water freezes and expands approximately 9% in volume, this molecular structure stretches to accommodate the pressure rather than cracking. The cross-linking density (typically 65-85% depending on PEX type) determines how much expansion the material can withstand before permanent deformation occurs.

This molecular flexibility contrasts sharply with rigid materials like copper or CPVC, which have crystalline structures that cannot stretch significantly. When subjected to freezing conditions, these materials develop stress concentrations that quickly exceed their tensile strength, resulting in cracks or bursts.

Material Memory and Elasticity

PEX exhibits what material scientists call “viscoelastic” behavior – it combines fluid-like and solid-like characteristics. This enables the pipe to slowly return toward its original shape after deformation, a property known as “shape memory.” Following a freeze event, PEX will typically recover most of its original dimensions as it thaws, though repeated freezing may cause some permanent deformation.

The material’s fatigue resistance allows it to withstand multiple expansion and contraction cycles. However, it’s important to note that while PEX can survive freezing, each event creates some molecular stress that accumulates over time, potentially reducing the material’s lifespan.

Table: Material Properties Affecting Freeze Resistance

| Property | PEX Advantage | Rigid Pipe Limitation | Impact on Freeze Survival |

|---|---|---|---|

| Elasticity | High – stretches under pressure | Low – minimal stretch capacity | PEX expands instead of cracking |

| Toughness | Excellent – absorbs impact energy | Brittle – fractures easily | PEX withstands ice formation |

| Memory Effect | Strong – returns toward original shape | None – permanent deformation | PEX recovers after thawing |

| Fatigue Resistance | Good – withstands repeated cycles | Poor – weakens with cycling | PEX survives multiple events |

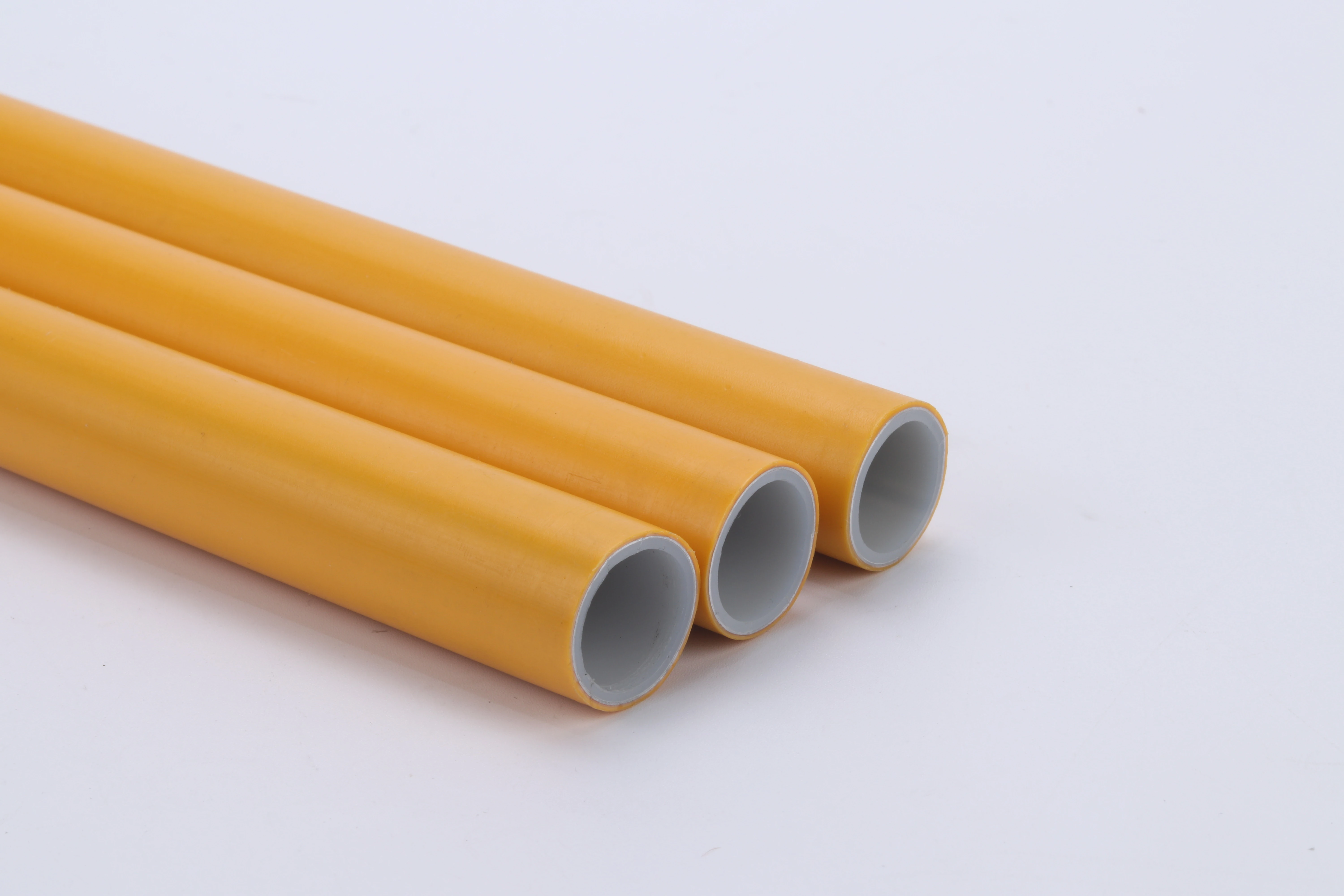

Comparative Performance by PEX Type

Not all PEX offers equal freeze resistance. PEX-A (manufactured using the Engel method) typically provides the best performance due to its higher cross-linking density and more uniform molecular structure. It can often expand up to 300% before failing and exhibits the strongest shape memory. PEX-B and PEX-C offer good freeze resistance but may not recover as completely after severe freezing events.

How does PEX’s flexibility compare to rigid pipes in freeze protection?

PEX’s flexibility provides a fundamental advantage in freeze protection that rigid pipes cannot match, though understanding the practical implications of this difference is essential for proper system design.

PEX’s flexibility allows it to absorb the expansion force of freezing water through dimensional changes rather than resisting until failure occurs. While copper and CPVC pipes typically burst at pressures around 1,000 PSI generated by ice expansion, PEX can expand to accommodate this pressure, often surviving freeze events that would destroy rigid piping systems.

The science behind PEX’s freeze resistance is standardized by industry bodies—you can review the official material performance criteria in the ASTM F876 Standard Specification for Cross-Linked Polyethylene (PEX) Tubing at ASTM International’s website, which outlines how cross-linking density impacts freeze tolerance.

Expansion Capacity Differences

When water freezes inside a pipe, it generates tremendous pressure – approximately 30,000 PSI if completely constrained. Rigid pipes attempt to contain this pressure through their structural strength, but even robust metals like copper (burst pressure around 1,000 PSI) cannot withstand these forces.

PEX takes a completely different approach by allowing controlled expansion. Instead of resisting the pressure, the pipe walls stretch to create additional volume for the expanding ice. This pressure-relieving action typically occurs at just 100-200 PSI, well below PEX’s burst pressure rating of 400-600 PSI at room temperature.

Failure Mode Comparison

The failure modes differ significantly between materials. Copper pipes typically develop longitudinal splits or burst at soldered joints when frozen. CPVC becomes increasingly brittle at low temperatures and often shatters into multiple fragments. Both failure types tend to be catastrophic, releasing significant water when thawing occurs.

PEX failures, when they occur, are typically more gradual. The material may develop a permanent bulge or “balloon” at the frozen section. While this deformation can restrict flow, it often doesn’t result in immediate leakage, providing an opportunity for detection and repair before major water damage occurs.

Table: Freeze Response Comparison Between Pipe Materials

| Response Characteristic | PEX Performance | Copper/CPVC Performance | Practical Implication |

|---|---|---|---|

| Initial Freeze Response | Expands to relieve pressure | Builds pressure until failure | PEX provides early warning |

| Typical Failure Mode | Bulging or slow leakage | Catastrophic bursting | PEX failures less destructive |

| Failure Pressure | 400-600 PSI (burst) | 1,000 PSI (copper) | PEX fails at higher pressure |

| Temperature Brittleness | Remains flexible to -40°F | Becomes brittle below freezing | PEX handles cold better |

Real-World Performance Evidence

Field experience and laboratory testing consistently demonstrate PEX’s superior freeze performance. In one controlled study, PEX-A pipes survived an average of 8 freeze-thaw cycles before developing leaks, while copper failed on the first freeze in most cases. However, it’s crucial to understand that survival doesn’t mean unaffected – each freeze event causes some permanent deformation that accumulates over time.

Insurance industry data reveals that PEX installations in cold climates experience approximately 70% fewer freeze-related claims compared to copper systems. This statistical advantage has led some insurers to offer premium discounts for homes with PEX plumbing, particularly in regions with severe winter conditions.

What installation techniques maximize PEX’s resistance to freeze damage?

Proper installation techniques significantly enhance PEX’s inherent freeze resistance, ensuring optimal performance when freezing conditions occur.

Strategic installation practices including proper support spacing, avoidance of sharp bends, adequate insulation, and elimination of water traps maximize PEX’s natural freeze resistance. Additionally, installing PEX with a slight drainage slope and using the correct PEX type for climate conditions further enhances performance in freezing environments.

Even the most freeze-resistant PEX can fail if improperly installed. These installation techniques leverage PEX’s material properties to provide the best possible freeze protection.

Routing and Support Strategies

Proper PEX routing can significantly reduce freeze susceptibility. Installing pipes through interior walls rather than exterior walls keeps them in warmer environments. When running through unconditioned spaces like attics or crawlspaces, keeping pipes close to the building’s warm interior provides additional protection.

Support spacing critically affects freeze resistance. Over-supported PEX cannot expand freely when freezing occurs, creating stress concentrations. Conversely, under-supported piping may sag and create low points where water collects and freezes. Following manufacturer spacing recommendations (typically 32 inches for horizontal runs) ensures proper support while allowing necessary expansion.

Directional Considerations and Fitting Placement

Creating gradual bends instead of using sharp elbows reduces flow resistance and minimizes potential freeze points. When direction changes are necessary, sweeping bends with a radius of at least 5-8 times the pipe diameter maintain optimal flow characteristics and allow uniform expansion during freezing.

Strategic fitting placement enhances freeze resistance. Positioning fittings in accessible, conditioned spaces facilitates inspection and repair if needed. Additionally, placing fittings away from exterior walls and other cold spots reduces their exposure to freezing conditions. Using fewer fittings overall, made possible by PEX’s flexibility, naturally reduces potential failure points.

Table: Installation Techniques for Freeze Protection

| Installation Technique | Procedure | Freeze Protection Benefit |

|---|---|---|

| Drainage Slope | 1/4 inch per foot downward slope | Allows water drainage from vulnerable sections |

| Interior Routing | Route through interior walls when possible | Keeps pipes in warmer environments |

| Proper Insulation | Use appropriate insulation thickness | Slows heat loss during cold exposure |

| Expansion Loops | Include in long straight runs | Accommodates thermal expansion/contraction |

| Accessible Fittings | Place in conditioned, accessible areas | Facilitates inspection and repair |

PEX Type Selection and System Design

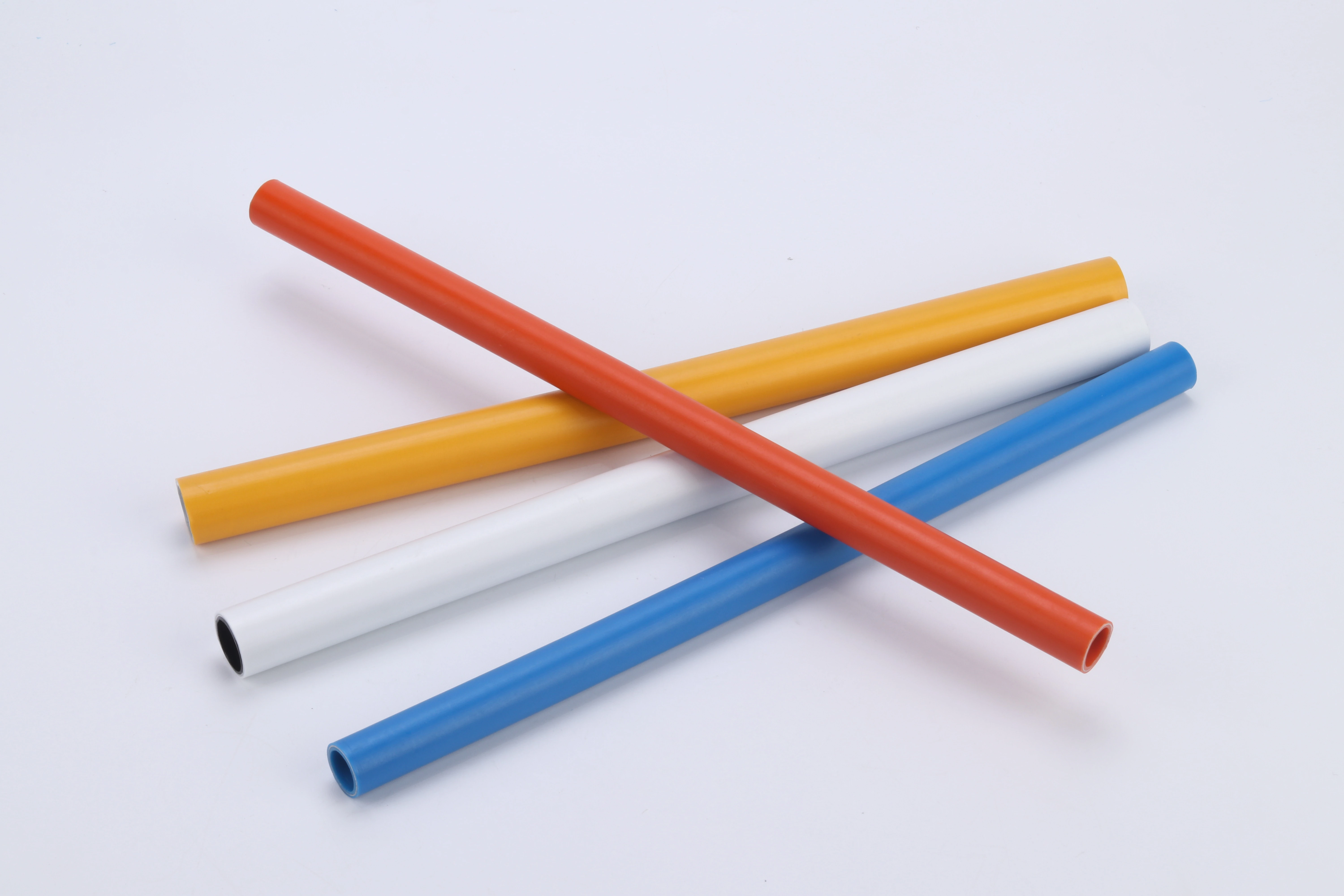

Choosing the appropriate PEX type enhances freeze resistance. PEX-A generally offers the best performance in freezing conditions due to its superior expansion recovery. For extreme climates, PEX-AL-PEX (aluminum-lined PEX) provides additional burst resistance while maintaining flexibility, though with slightly reduced expansion capacity.

System design considerations include installing automatic drain valves at low points in seasonal installations and incorporating isolation valves to compartmentalize potential freeze damage. In whole-house systems, designing with a “freeze protection zone” concept—keeping most piping within the building’s thermal envelope—maximizes inherent freeze resistance.

How should you maintain PEX pipes after exposure to freezing temperatures?

Proper maintenance following freeze exposure ensures PEX pipes continue to perform reliably and helps identify damage before it causes significant problems.

After freeze exposure, carefully inspect PEX pipes for bulges, deformations, or leaks as they thaw naturally, test system pressure gradually, and monitor for flow restrictions. Additionally, document any freeze events and corresponding pipe conditions to establish a maintenance history that helps predict long-term performance and replacement needs.

Post-freeze maintenance is crucial for identifying damage and preventing future issues. These procedures help maximize PEX’s service life even after freeze exposure.

Thawing and Initial Inspection

Allow frozen PEX to thaw naturally at room temperature rather than applying external heat. Artificial heating can create uneven expansion and stress points that may lead to failure. During thawing, keep faucets open to relieve pressure and allow visual monitoring of water flow resumption.

Conduct a thorough visual inspection once pipes have completely thawed. Look for:

- Bulges or expanded sections indicating permanent deformation

- Whitening or discoloration suggesting material stress

- Visible cracks or splits, particularly near fittings

- Moisture accumulation indicating slow leaks

Document findings with photographs and notes, paying special attention to pipes in vulnerable locations like exterior walls, attics, and crawlspaces.

Pressure Testing and Flow Assessment

After visual inspection, conduct a pressure test to identify leaks not visible during normal operation. Gradually increase system pressure to normal operating levels while monitoring for pressure drops. A sudden drop indicates significant leaks, while a gradual decline may suggest minor seepage.

Check flow rates at various fixtures to identify restrictions caused by pipe deformation. Significantly reduced flow may indicate bulging that has restricted the pipe interior. Compare flow rates between similar fixtures to identify localized issues.

Table: Post-Freeze Maintenance Procedures

| Maintenance Step | Procedure | Frequency | Documentation |

|---|---|---|---|

| Visual Inspection | Check for bulges, discoloration, moisture | After each freeze event | Photograph and note locations |

| Pressure Testing | Test at operating pressure for 1 hour | After significant freeze events | Record pressure readings |

| Flow Rate Check | Measure fixture flow rates | After any freeze event | Document reductions |

| Fitting Inspection | Check for leaks at connections | After thawing | Note fitting types and locations |

| System Flushing | Flush to remove debris | If deformation detected | Record sediment type |

Long-Term Monitoring and Prevention

Pipes that have experienced freezing should receive more frequent inspections, as the material may have sustained cumulative damage not immediately apparent. Monitor previously frozen sections during subsequent cold spells, as these areas may have become more susceptible to freezing.

Implement preventive measures based on freeze history:

- Add insulation to areas with previous freezing

- Improve airflow to cold spots where pipes are located

- Install heat tracing on vulnerable sections

- Consider pipe replacement if significant deformation occurred

Maintain a freeze event log documenting dates, temperatures, affected sections, and observed damage. This history helps identify patterns and prioritize preventive improvements.

Conclusion

PEX pipes can withstand freezing and thawing cycles significantly better than traditional rigid pipes due to their flexible molecular structure that allows expansion when water freezes. However, they are not freeze-proof, and proper installation techniques including appropriate routing, support spacing, and insulation maximize this inherent advantage. Following freeze exposure, careful inspection, pressure testing, and documentation ensure continued reliable performance. While PEX’s freeze resistance represents a major advancement in plumbing safety, preventive measures remain essential in cold climates, and even PEX will eventually fail if repeatedly frozen. Understanding both PEX’s capabilities and limitations allows homeowners and professionals to leverage its advantages while implementing appropriate safeguards against freeze damage.

Recent Comments