When building high-performance piping systems in Europe—whether for residential water supply, commercial plumbing, or industrial applications—PPR elbow fittings play a vital role in redirecting flow while withstanding pressure. But just how reliable are these fittings under pressure?

In this blog, we’ll explore the pressure-resistant performance of PPR elbow fittings, including standard ratings, European certifications, and what makes them a dependable choice for modern piping systems.

✅ What Are PPR Elbow Fittings?

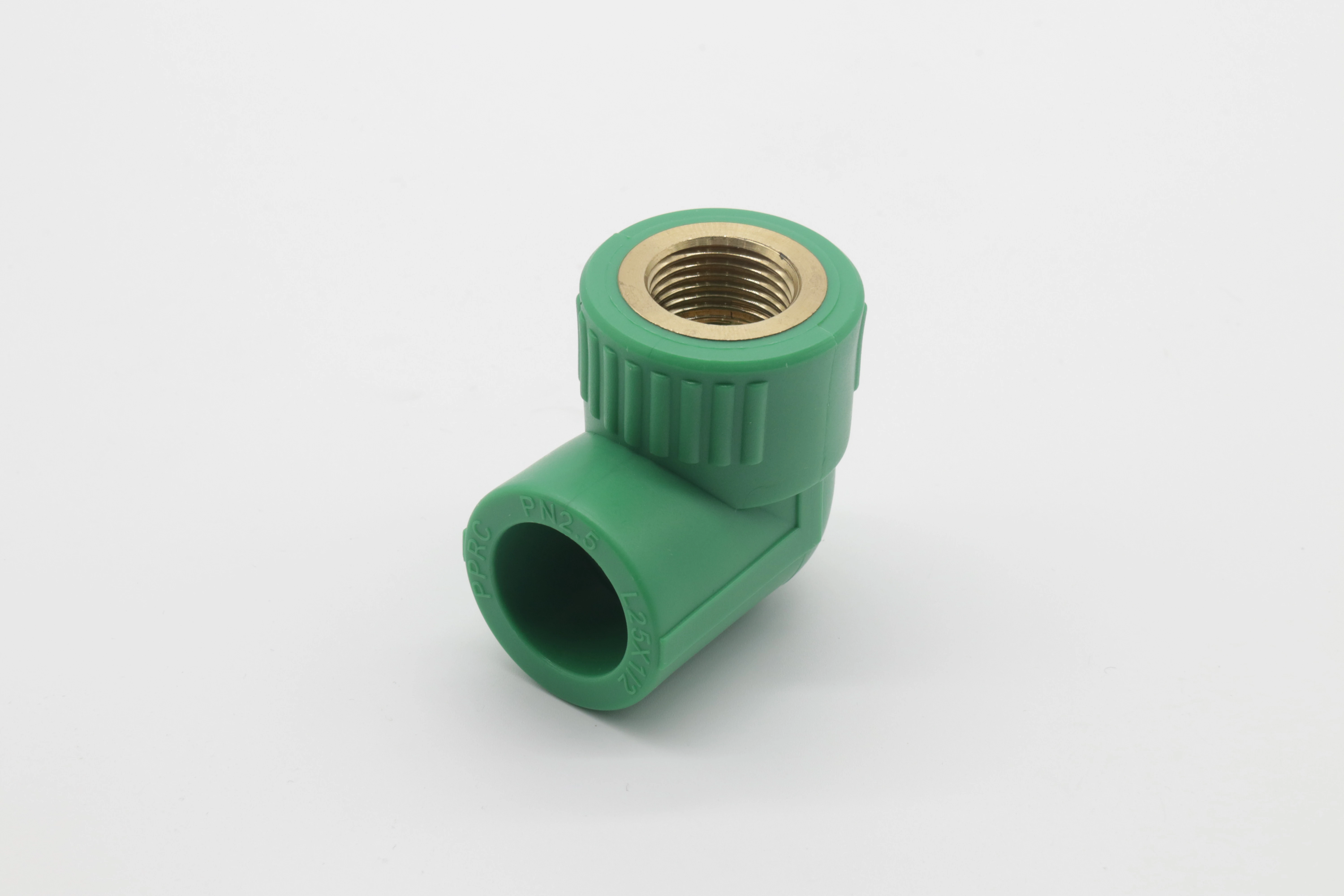

PPR (Polypropylene Random Copolymer) elbow fittings are used to change the direction of a PPR pipe system, commonly at 90° or 45° angles. These fittings are heat-fused to the pipe, creating a seamless, leak-proof connection.

They are widely used in:

- Hot and cold water systems

- Central heating systems

- Industrial liquid transport

- Compressed air pipelines

💪 Pressure-Resistant Properties of PPR Elbow Fittings

One of the core strengths of PPR elbow fittings is their resistance to internal pressure, even at elevated temperatures.

📌 Key Performance Indicators:

| Property | Value |

|---|---|

| Max Working Pressure | Up to 25 bar (PN25) |

| Max Operating Temperature | Up to 95°C (continuous) |

| Burst Pressure (Short-term) | Up to 70–100 bar, depending on size & thickness |

| Life Expectancy | 50+ years under standard conditions |

Note: Pressure tolerance decreases with temperature increase. Always refer to manufacturer pressure-temperature charts.

🏷️ Common Pressure Ratings in Europe

In Europe, PPR elbow fittings are classified into pressure nominal classes, commonly:

- PN10 – Cold water systems (≤45°C)

- PN16 – Mixed hot/cold water (up to 70°C)

- PN20 – Domestic hot water (up to 80°C)

- PN25 – High-pressure or heating systems (up to 95°C)

✅ For high-pressure or high-temperature use, PN20 and PN25 elbows are preferred.

📋 European Standards and Certifications

To ensure pressure safety, PPR elbow fittings must comply with:

- DIN 8077 / 8078: German standard for PPR pipe dimensions and quality

- ISO 15874: International standard for hot and cold water piping systems

- CE Certification: Required for products entering the European market

Make sure to source from manufacturers who offer third-party tested and certified products to meet regional building codes.

🔎 Factors That Affect Pressure Resistance

- Wall Thickness & Pipe Diameter

Thicker walls and smaller diameters generally increase pressure resistance. - Fusion Quality

Proper heat fusion welding ensures joints maintain full pressure integrity. - Material Grade

High-quality Type 3 PPR offers better thermal and mechanical performance. - Operating Environment

Long-term exposure to high heat or chemicals can affect fitting durability.

🌍 European Market Expectations

European engineers, builders, and plumbing contractors prioritize:

- Long-term performance under pressure

- Consistent product standards

- Easy traceability and compliance with EU directives

That’s why many importers and wholesalers in Europe partner with certified overseas manufacturers like ifanpro to source high-quality PPR elbow fittings at competitive pricing.

🏭 Why Choose ifanpro PPR Elbow Fittings?

As a trusted PPR pipe and fitting manufacturer from China, ifanpro offers:

- ✅ DIN/ISO-certified elbow fittings (PN16, PN20, PN25)

- ✅ 100% virgin PPR material for maximum strength

- ✅ Custom angles and OEM branding for distributors

- ✅ Strict quality control + pressure testing for each batch

- ✅ Fast global shipping and multilingual support

👉 Visit ifanpro.com to browse our full catalog or request a free quote.

✅ Conclusion

PPR elbow fittings are engineered to withstand high pressure and temperature variations, making them a reliable choice for European plumbing and heating systems. When sourced from certified manufacturers like ifanpro, you can expect durable, leak-proof performance for decades—backed by international standards and local compliance.

Recent Comments