When it comes to choosing the right piping material for your plumbing, water supply, or construction project, two of the most common options are PPR (Polypropylene Random Copolymer) and PVC (Polyvinyl Chloride). But which one is better?

The answer depends on your application, temperature and pressure requirements, installation methods, and long-term performance goals. In this guide, we break down the key differences between PPR and PVC pipes, helping you make the most informed decision.

🔍 What Is the Main Difference Between PPR and PVC?

| Feature | PPR (Polypropylene Random Copolymer) | PVC (Polyvinyl Chloride) |

|---|---|---|

| Temperature Resistance | High (up to 95°C) | Low to Medium (up to 60°C) |

| Pressure Tolerance | Excellent | Good (for low-pressure systems) |

| Lifespan | 50+ years | 20–40 years |

| Toxicity | Non-toxic, BPA-free | May contain chlorine and additives |

| Joining Method | Heat fusion welding (leak-proof) | Solvent glue (chemical bonding) |

| Flexibility | More flexible | Rigid and brittle under stress |

| Best Use | Hot & cold water, heating, industry | Cold water, drainage, electrical conduit |

✅ Advantages of PPR Pipes

- High Temperature Resistance

Ideal for hot water plumbing, HVAC, and underfloor heating, PPR pipes maintain performance even at 95°C (203°F) continuously. - Leak-Free Welding

PPR pipes are joined by heat fusion, creating a monolithic system that is completely leak-proof—ideal for high-pressure systems. - Safe for Drinking Water

PPR is non-toxic, heavy metal-free, and BPA-free, making it perfect for potable water systems in homes, hotels, and hospitals. - Long-Term Durability

With a lifespan of over 50 years, PPR pipes resist corrosion, scaling, and chemical attack better than PVC in long-term applications. - Environmental Benefits

PPR is recyclable, energy-efficient to manufacture, and aligns with European environmental standards for sustainable construction.

✅ When to Choose PVC Pipes

PVC pipes still offer value in certain applications:

- Low-cost cold water systems

- Drainage and wastewater piping

- Electrical conduit protection

However, PVC is not suitable for hot water and may degrade or deform when exposed to high temperatures or pressure over time.

🏗️ Common Use Cases

| Application | Recommended Material |

|---|---|

| Hot Water Plumbing | PPR |

| Cold Water Plumbing | PPR or PVC |

| HVAC Systems | PPR |

| Drainage and Wastewater | PVC |

| Drinking Water Supply | PPR |

| Chemical/Industrial Applications | PPR |

| Electrical Cable Protection | PVC |

🌍 Market Insight: Why PPR Is Preferred in Modern Construction

In Europe, the Middle East, and increasingly in Asia, PPR pipes are replacing PVC in high-performance projects due to better temperature handling, health safety, and lifecycle costs.

Builders and contractors prefer PPR for:

- Green building certifications (LEED, BREEAM)

- Energy-efficient heating systems

- Safe water distribution in schools, hospitals, and homes

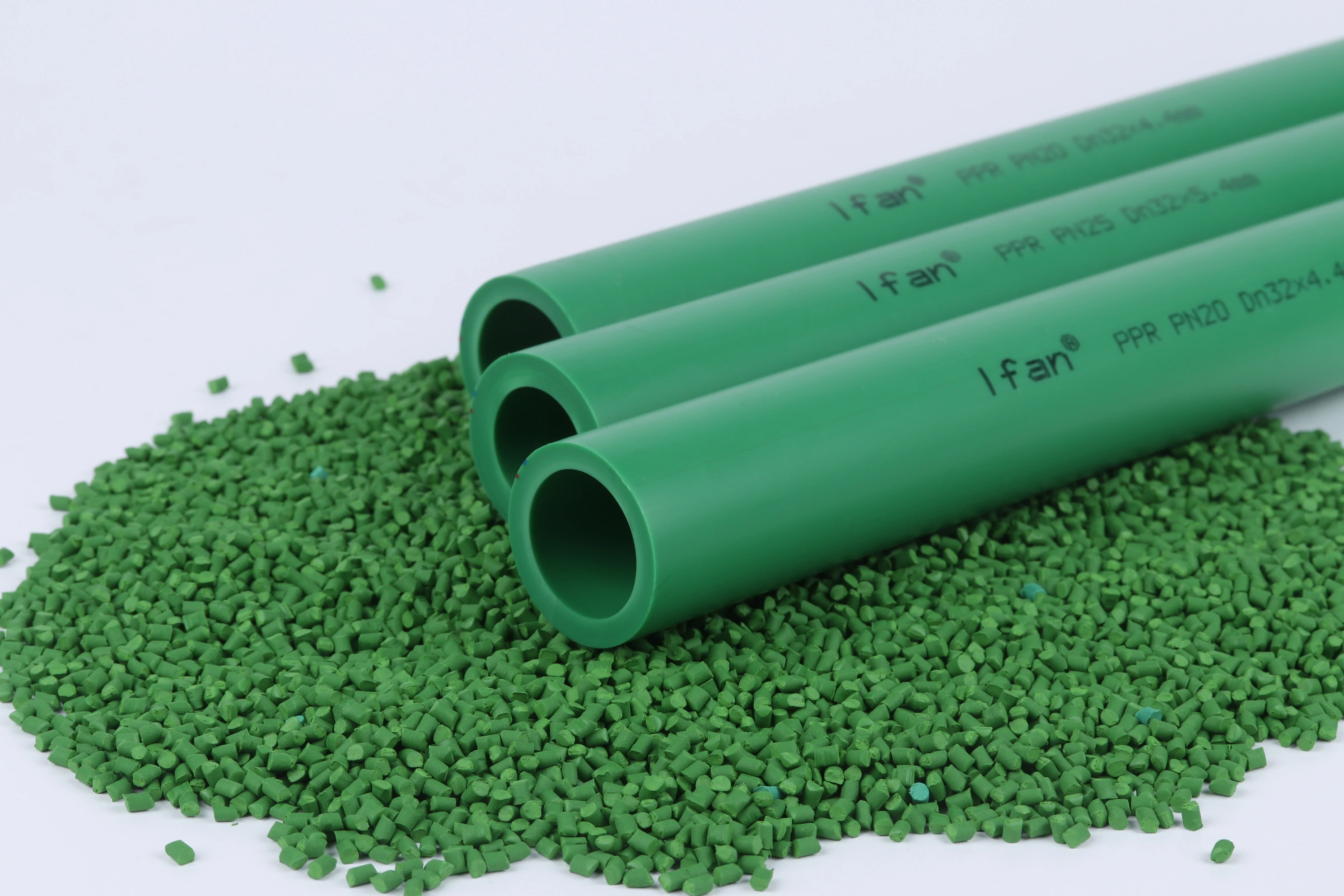

🔧 Looking for a Reliable PPR Pipe Supplier?

At ifanpro, we are a professional PPR pipe and fitting manufacturer from China. We specialize in:

- DIN and ISO-certified PPR systems

- Hot & cold water pipes, fittings, and valves

- Full customization and OEM services for global partners

- Factory-direct support for wholesalers and project contractors

✅ Trusted by customers across Europe, the Middle East, and South America for long-lasting, high-performance piping solutions.

✅ Conclusion: PPR or PVC – Which Should You Choose?

- Choose PPR if you need a durable, leak-proof, and safe solution for hot water, heating, or high-pressure systems.

- Choose PVC if you’re installing basic cold water or drainage systems on a limited budget.

In modern, eco-conscious construction, PPR is the better long-term investment—offering safety, performance, and environmental benefits in one.

Recent Comments