Table of contents

隐藏

1. Introduction: The Critical Role of PPR Plastic Unions in Modern Plumbing Systems

- Explain what a PPR plastic union is (a detachable pipe fitting for easy installation, maintenance, and repairs).

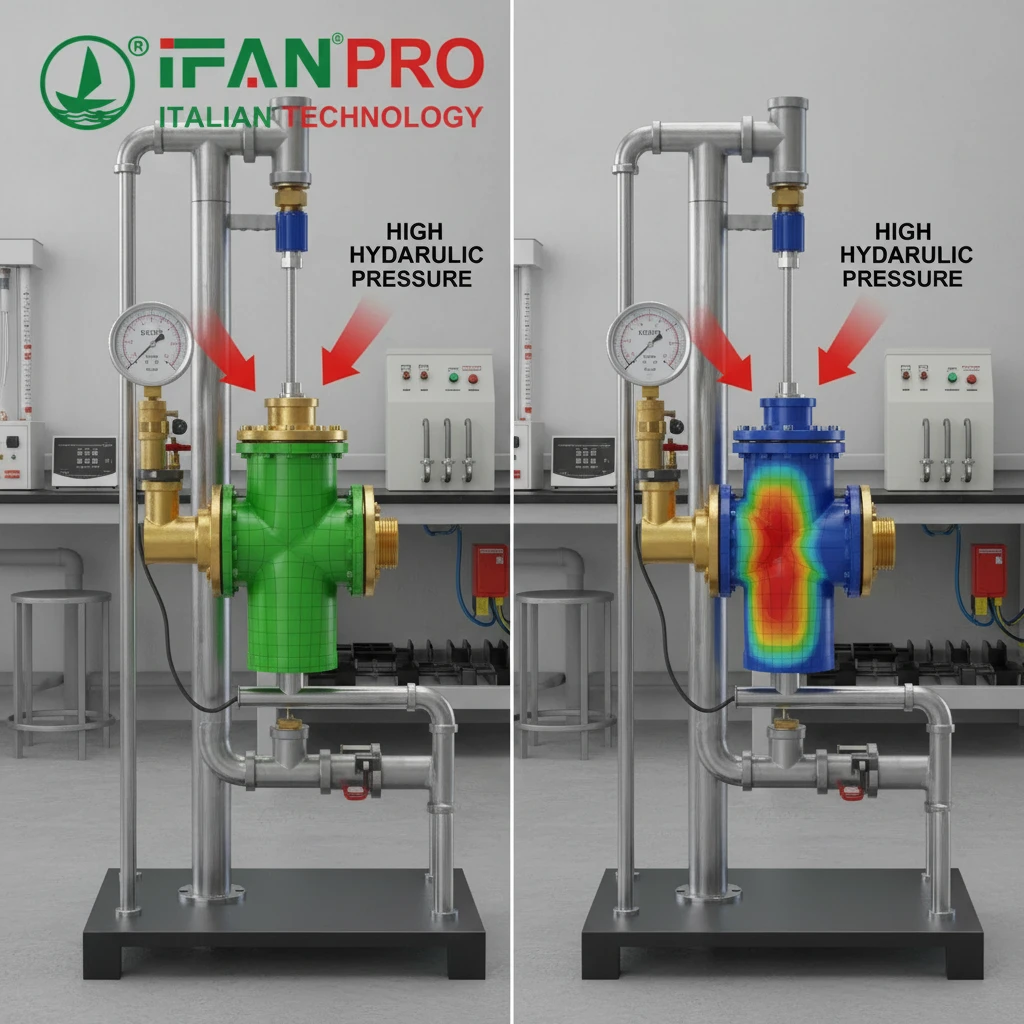

- Highlight the risks of low-quality unions: leaks, corrosion, and costly system downtime.

- Position high-quality PPR unions as a cornerstone for durable, efficient pipe networks in residential, commercial, and industrial applications.

2. Key Features of Premium PPR Plastic Unions

- Superior Material Composition:

- Food-grade PPR (polypropylene random copolymer) for non-toxic, corrosion-resistant performance (ideal for potable water systems).

- High-temperature resistance (up to 70°C continuously, 95°C short-term) and pressure tolerance (16–20 bar), meeting 严苛 industrial standards.

- Design for Easy Installation & Leak-Proof Sealing:

- Dual Union Design: Two female threaded ends with a central nut for quick disassembly without system shutdown.

- Integral Rubber Gasket: High-density EPDM or NBR gaskets for airtight/watertight seals, even under pressure fluctuations.

- Smooth Inner Bore: Reduces flow resistance and prevents sediment buildup, enhancing system efficiency.

- Compliance with International Standards:

- Certifications: ISO 9001, SGS, CE, NSF 61 (for potable water), or KTW (Germany) for safety and reliability.

- Testing: Burst pressure tests (3x rated pressure), thermal cycling, and long-term creep resistance to ensure 50+ years of service life.

3. Where to Use High-Quality PPR Plastic Unions: Diverse Application Scenarios

- Residential Plumbing:

- Connecting water heaters, boilers, or filtration systems for easy replacement without cutting pipes.

- Ideal for under-sink installations or shower valve connections where accessibility is key.

- Commercial & Industrial Systems:

- HVAC systems (hot/cold water loops), industrial pipelines (chemical-resistant for non-corrosive fluids), and irrigation networks.

- Maintenance-friendly solutions for large-scale projects (e.g., hotels, hospitals, or manufacturing plants).

- Renovation & Retrofit Projects:

- Retrofitting old metal unions with lightweight PPR alternatives to reduce system weight and eliminate rust-related issues.

- Compatibility with both PPR pipes (via socket fusion) and metal/PEX pipes (via threaded connections).

4. How to Select the Right PPR Plastic Union: Key Buying Criteria

- Material & Construction:

- Avoid recycled materials (check for uniform color and smooth surface texture).

- Opt for virgin PPR copolymer (marked as “PPR Type 3”) for superior impact and heat resistance.

- Size & Compatibility:

- Nominal diameters (DN15–DN100) and thread types (BSP, NPT, metric) to match your pipeline system.

- Ensure the union’s pressure rating (e.g., PN16, PN20) exceeds your system’s maximum operating pressure.

- Seal Design & Durability:

- Prefer unions with replaceable gaskets (for easy maintenance) and UV-stabilized materials if used outdoors.

- Check for “anti-rotation” features (e.g., hexagonal nuts with grip texture) to prevent over-tightening.

- Supplier Credibility:

- Look for manufacturers with in-house extrusion and molding capabilities (ensures quality control from raw material to finished product).

- Request factory audit reports or video tours to verify production standards (e.g., automated welding, leak testing lines).

5. Red Flags: How to Avoid Low-Quality PPR Unions

- Warning Signs of Inferior Products:

- Vague product specifications (no listed pressure/temperature ratings or certification details).

- Excessive burrs on threads, misaligned gasket seats, or brittle plastic (fails a simple “snap test” when bent).

- Prices below $1.00 for DN20 unions (quality unions typically range $1.50–$5.00, depending on size).

- Questions to Ask Suppliers:

- “What is the union’s minimum burst pressure at 20°C?” (Expect ≥40 bar for PN20-rated products).

- “Do you offer customized packaging or branding for bulk orders?” (Critical for distributors/wholesalers).

- “Can I get a free sample to test compatibility with my existing fittings?” (Non-negotiable for large purchases).

6. Why Partner with a Reputable PPR Union Manufacturer?

- Factory-Direct Advantages:

- Eliminate middlemen markups: Competitive pricing for bulk orders (MOQs as low as 500 units for standard sizes).

- OEM/ODM Capabilities: Customize thread types, colors, or logos (e.g., blue unions for cold water, red for hot water).

- Technical Support & Logistics:

- Free installation guides and compatibility charts for complex systems.

- Global shipping with DDP options, plus export packaging (palletized, shrink-wrapped) to prevent transit damage.

- Case Study: How a Turkish Wholesaler Boosted Profits with High-Quality Unions

- A client reduced return rates by 60% after switching to a supplier with 100% pre-shipment leak testing, improving customer loyalty.

7. Ready to Source Premium PPR Plastic Unions? Your Step-by-Step Guide

- Step 1: Define Your Requirements:

- List pipe diameter, thread type, required pressure/temperature ratings, and quantity (include a downloadable specs checklist).

- Step 2: Evaluate Suppliers:

- Compare certifications, sample quality, and lead times (2–3 weeks for standard orders, 4–6 weeks for custom designs).

- Step 3: Secure Your Order:

- Request a quote that includes testing reports, warranty terms (e.g., 5-year guarantee), and after-sales support.

8. Call to Action: Elevate Your Pipeline with Reliable PPR Unions

- Encourage readers to:

- Visit your website to explore the full range of PPR unions (link to product page with size/price filters).

- Download a free PDF: “10 Must-Check Criteria for PPR Union Quality” (gate with email capture for lead nurturing).

- Contact your team for a personalized consultation, including free samples and CAD drawings for custom projects.

Conclusion: Quality PPR Unions—A Small Component, a Big Impact on System Reliability

Reinforce that investing in high-quality PPR plastic unions is a strategic decision to avoid costly failures and ensure long-term performance. Position your brand as a trusted partner with technical expertise and a commitment to delivering solutions that meet global standards.

Recent Comments