Table of contents

隐藏

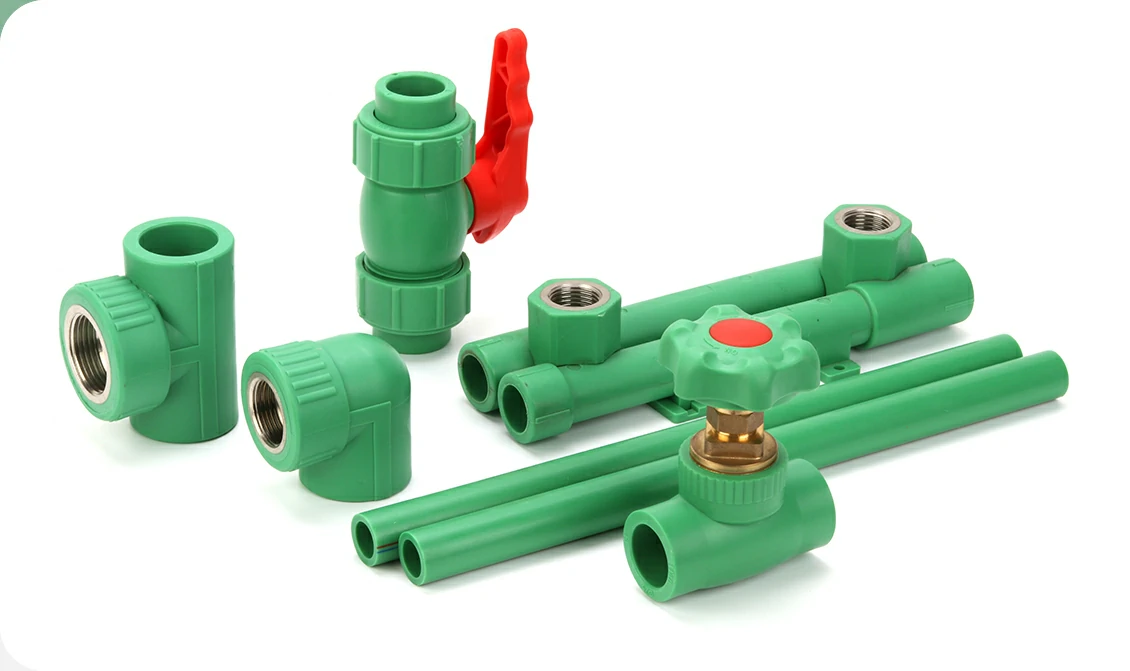

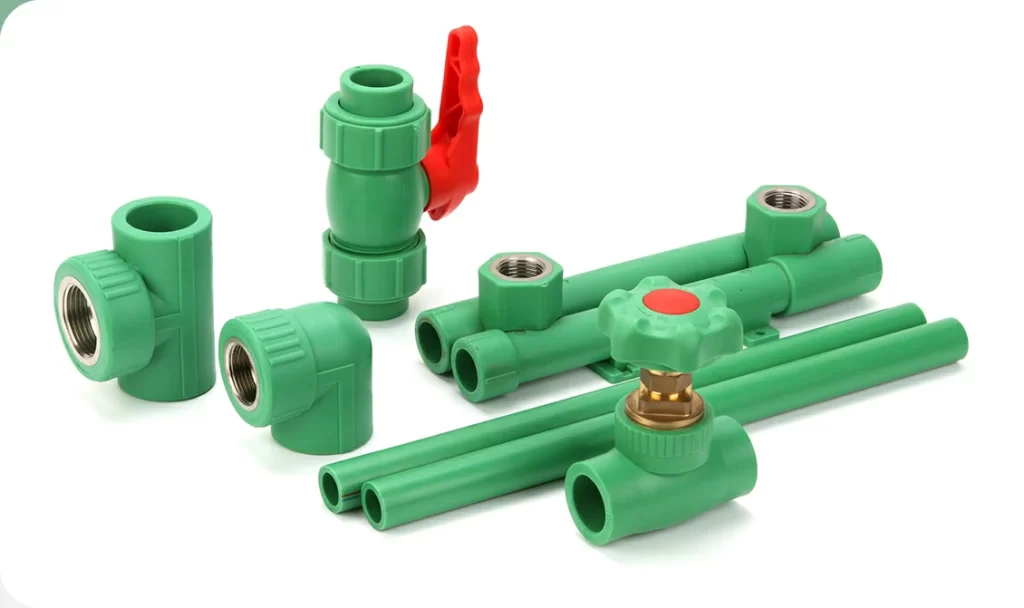

1. Introduction: The Growing Popularity of PPR Pipes in Drinking Water Systems

- Brief overview of PPR (polypropylene random copolymer) as a leading material for potable water pipelines due to its safety, durability, and cost-effectiveness.

- Pose the core question: “How long do PPR pipes typically last in drinking water applications?” to align with user search intent.

- Establish credibility: As a trusted manufacturer (IFAN Pro), explain why lifespan is a critical factor for homeowners, plumbers, and industrial buyers, and hint at actionable insights ahead.

2. Typical Lifespan of PPR Pipes in Drinking Water Systems

- Standard Lifespan Range: 50–70 years under optimal conditions (backed by industry standards like ISO 15874 and manufacturer warranties).

- Key Differentiator: PPR’s molecular structure resists chemical degradation and bacterial growth, making it superior to older materials like iron or PVC for potable water.

- Real-World Example: Cite a case study of a residential complex in California that replaced galvanized steel with PPR pipes in 2005—no leaks or degradation reported after 18 years of use.

3. 5 Critical Factors That Affect PPR Pipe Lifespan

(Use H2 subheadings for each factor to improve SEO and readability)

3.1 Material Quality & Manufacturing Standards

- Importance of food-grade PPR raw materials (e.g., compliant with NSF 61, WRAS, or KTW for drinking water safety).

- Warning: Low-quality PPR with recycled polymers may degrade in 10–15 years due to UV or chemical exposure.

3.2 Operating Temperature & Pressure

- Temperature Impact:

- Ideal range: 0–70°C (PPR maintains full integrity).

- Prolonged exposure above 70°C (e.g., uninsulated hot water lines) can reduce lifespan by 20–30%.

- Pressure Limits: Rated for 10–20 bar (check manufacturer specs; sustained overpressure increases stress on joints).

3.3 Installation Practices

- Poor fusion welding (for socket-jointed PPR) causes micro-leaks, leading to bacterial buildup and accelerated corrosion.

- Incorrect support spacing (e.g., sagging pipes under heavy loads) creates mechanical stress points.

3.4 Water Quality & Chemical Exposure

- High pH (alkaline) or chlorinated water is generally safe for PPR, but abrasive particulates (e.g., sand) can erode inner walls over decades.

- Avoid direct contact with strong solvents (e.g., gasoline), though PPR is resistant to most household chemicals.

3.5 Environmental Conditions

- Underground vs. above-ground installation: Buried PPR (with proper coating) lasts longer than exposed pipes in UV-rich climates (add UV stabilizers for outdoor use).

- Freeze-thaw cycles: PPR’s flexibility reduces cracking risk, but proper insulation is still critical in sub-zero regions.

4. PPR vs. Alternative Materials: A Lifespan Comparison

| Material | Typical Lifespan (Drinking Water) | Key Drawbacks |

|---|---|---|

| PPR | 50–70 years | Requires specialized fusion tools for installation |

| PVC (uPVC) | 20–40 years | Susceptible to chlorine degradation; not ideal for hot water |

| Copper | 40–50 years | Higher cost; prone to pitting in acidic water |

| PE (Polyethylene) | 30–50 years | Lower temperature resistance (max 40°C) |

- Conclusion: PPR outperforms most materials for long-term, safe drinking water distribution.

5. How to Maximize the Lifespan of Your PPR Pipes

- Pro Tip 1: Choose Certified Products

- Look for third-party certifications (e.g., NSF, CE, SGS) to ensure compliance with drinking water safety standards.

- Pro Tip 2: Proper Installation by Trained Professionals

- Use fusion welding equipment with precise temperature control (260±5°C for PPR) and follow ISO 21307 guidelines.

- Pro Tip 3: Regular Maintenance

- Annual visual inspections for leaks or joint wear.

- Flush pipelines every 5–7 years to remove sediment buildup (critical for hard water areas).

- Pro Tip 4: Protect Against Extreme Conditions

- Insulate hot water lines to maintain optimal temperature and prevent condensation.

- Add a sacrificial anode for underground installations in highly corrosive soil.

6. What to Look for When Buying PPR Pipes for Drinking Water

- Material Purity: Ask suppliers for raw material certificates (e.g., from LyondellBasell or Borealis, top PPR resin producers).

- Wall Thickness & Pressure Rating: Match to your system’s requirements (e.g., SDR11 for high-pressure applications).

- Manufacturer Warranty: Reputable brands like IFAN Pro offer 50-year warranties, backed by rigorous testing (link to ifanpro.com PPR pipe product page).

7. Conclusion: Invest in Quality for Long-Lasting, Safe Water Supply

- Recap: PPR pipes can last 50+ years in drinking water systems when paired with high-quality materials, proper installation, and basic maintenance.

- Address user intent: Reassure buyers that PPR is a future-proof choice for residential, commercial, and municipal projects.

- Call to Action (CTA):

- Visit ifanpro.com to explore our certified PPR pipe solutions for drinking water applications.

- Download our free guide: “10 Tips for Selecting PPR Pipes for Potable Water Systems” (link to a gated resource or blog post).

Recent Comments