Introduction

Brass fittings, a staple in industrial manufacturing, play a pivotal role in ensuring the seamless flow of fluids and gases across various systems. Known for their durability, corrosion resistance, and versatility, they form the backbone of countless industries, from plumbing to oil and gas. This article delves into the significance of brass fittings, their unique properties, applications, manufacturing processes, maintenance considerations, environmental impact, future trends, and the critical role they play in enhancing industrial efficiency.

Unique Properties of Brass Fittings

Brass, an alloy primarily composed of copper and zinc, boasts a range of properties that make it ideal for fittings. Its resistance to corrosion, especially in wet environments, ensures long-lasting performance. Moreover, brass’s machinability allows for precise manufacturing, ensuring tight seals and leak-free connections. Its natural antibacterial properties further enhance its suitability for applications where hygiene is paramount.

Versatile Applications Across Industries

Brass fittings find widespread use across industries. In plumbing, they connect pipes efficiently, ensuring water and gas distribution without leaks. The oil and gas sector relies on brass fittings for their high-pressure tolerance and ability to withstand harsh chemicals. Automotive manufacturers incorporate brass fittings in cooling systems and fuel lines due to their durability and reliability. Even the electronics industry leverages brass’s conductivity in components like connectors and terminals.

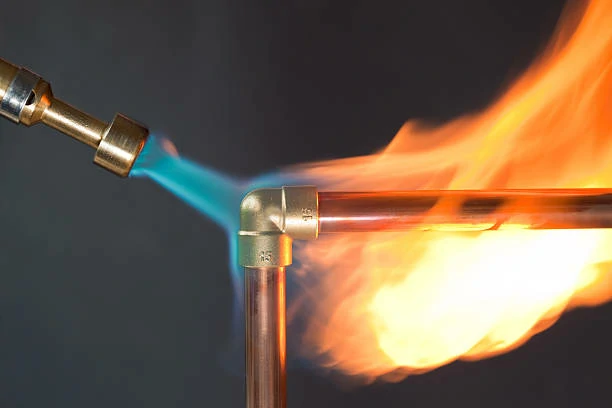

Manufacturing Processes: Precision and Craftsmanship

The production of brass fittings involves intricate processes that blend modern technology with traditional craftsmanship. Raw brass ingots are melted and poured into molds, creating the basic shapes. Subsequent machining operations, including drilling, threading, and polishing, refine these shapes into precise fittings. Automated machinery ensures consistency and accuracy, while skilled workers inspect each fitting for quality assurance. The result is a product that meets stringent industry standards.

Maintenance and Longevity

Maintaining brass fittings is crucial for ensuring their longevity and optimal performance. Regular inspections for leaks, corrosion, and wear are essential. Cleaning fittings with mild detergents and avoiding harsh chemicals can preserve their finish. In case of damage, prompt replacement is necessary to prevent system failures. Proper installation, using appropriate sealants and torque specifications, also contributes to the long-term success of brass fittings.

Environmental Considerations

As with any industrial material, brass fittings have environmental implications. While brass is recyclable, the mining and refining of raw materials can have an impact. Manufacturers are increasingly adopting sustainable practices, such as using recycled brass and optimizing production processes to minimize waste. Additionally, the durability of brass fittings reduces the need for frequent replacements, thereby lowering the overall environmental footprint.

Future Trends and Innovations

The future of brass fittings is marked by innovation and adaptability. As industries continue to evolve, brass fittings will need to meet new challenges, such as higher pressure ratings, improved corrosion resistance, and compatibility with alternative energy sources. Manufacturers are investing in research and development to create next-generation fittings that incorporate advanced materials and designs. Smart fittings, incorporating sensors and IoT technology, may also emerge, enhancing system monitoring and maintenance.

Critical Role in Enhancing Industrial Efficiency

Brass fittings are more than just components; they are the lifeblood of industrial systems. Their reliability and durability ensure continuous operation, minimizing downtime and maximizing productivity. By reducing leaks and ensuring efficient fluid flow, brass fittings contribute to energy savings and cost reductions. Moreover, their versatility allows for easy integration into existing systems, facilitating upgrades and expansions.

Conclusion

In conclusion, brass fittings stand as the solid foundation of industrial manufacturing. Their unique properties, versatility, and durability make them indispensable across a wide range of industries. As the world continues to advance, brass fittings will evolve to meet new challenges, incorporating innovations that enhance their performance and sustainability. The ongoing commitment to quality, craftsmanship, and environmental responsibility ensures that brass fittings will remain a vital component of industrial progress for years to come.

| TOP 6 Brass products Manufacturers | ||

| Companies | Headquarter/Location | Year Founded |

| IFAN | ZHEJIANG,CHINA | 1993 |

| RAKtherm | UAE | 1963 |

| REHAU | Muri bei Bern, Switzerland | 1948 |

| POLOPLAST | Leonding, Austria | 1954 |

| ERA | ZHEJIANG,CHINA | 1983 |

| LESSO | GUANGDONG,CHINA | 1986 |

IFAN Products international standards

IFAN products strictly adhere to a comprehensive range of international standards, encompassing ISO 15874, EN 15874, ASTM F2389, DIN 8077/8078, GB/T 18742, NBR 15884, ISO 15494, EN ISO 15494, GB/T 19472, NBR 15494, ASTM 2846 (501), DIN 8079/8080 (502), ASTM F441/F441M SCH80 (503), DIN (504), DIN (505), GB/T 18993, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, TIS 17-2532/1131-2535, BS 3505, BS 4346 (801), ASTM D1785 SCH40 (802), ASTM D1785 SCH80 (803), DIN (804), GB (805), GB (806), GB(901), DWV(902), ASTM D2665 (903), along with ASTM D2241, D2665, D2729, and F441/F441M series, ISO 1452, EN ISO 1452, DIN 8061/8062, GB/T 10002, AS/NZS 1477, JIS K6741, CSA B137.3, and other national and industry norms. They ensure that products, from piping systems to material properties, meet the highest international standards, including but not limited to ISO 4437, EN 1555, DIN 8074/8075, GB/T 13663, AS/NZS 4130, BS 5405, CSA B137.1, JIS B 8381, and specific material standards such as ASTM D3035, D3350, ISO 4427, EN 12201, JIS K6760, BS 6572. They also cover stainless steel piping (e.g., ASTM A312) and standards for specialized applications (e.g., GB-T12777-2019, ISO 10380-2012, ASTM F2623), comprehensively satisfying the stringent global demands for high-quality products.

Connect

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interest in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://ifanpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Recent Comments