Understanding the Need for Transition

Why Transition to Brass?

Transitioning from plastic piping to brass plumbing offers several benefits. Brass is more durable, resistant to corrosion, and can handle higher temperatures and pressures. This makes it ideal for various plumbing applications, including hot water lines and outdoor installations.

Common Issues with Plastic Piping

Plastic piping, while affordable and easy to install, has limitations. It can degrade over time, become brittle, and is susceptible to damage from UV exposure. Brass plumbing provides a more robust and long-lasting solution.

Planning the Transition

Assessing the Existing System

Before starting the transition, assess the current plumbing system. Identify the types of plastic pipes used (e.g., PVC, PEX), their sizes, and connection points. This will help in planning the necessary steps and materials required for the transition.

Determine the Scope of the Transition

Decide whether to replace the entire plastic piping system or only specific sections. Complete replacement offers a uniform and reliable system but may be more costly and time-consuming. Partial replacement can address problem areas while keeping costs down.

Choosing the Right Brass Components

Selecting Brass Pipes and Fittings

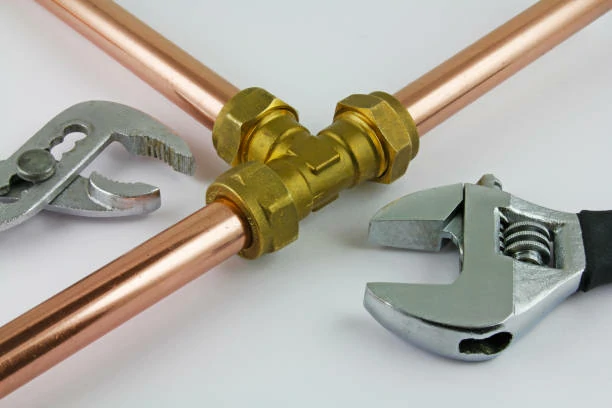

Choose high-quality brass pipes and fittings. Ensure they meet the required specifications for your plumbing system, including pressure and temperature ratings. Brass fittings come in various types, such as elbows, tees, couplings, and adapters.

Lead-Free Brass

For potable water systems, ensure the brass components are lead-free. This prevents lead contamination and ensures compliance with health and safety standards.

Compatibility with Existing System

Select brass fittings that are compatible with the existing plastic pipes. Transition fittings, such as brass-to-plastic adapters, are available to facilitate the connection between different materials.

Transition Fittings and Adapters

Using Transition Fittings

Transition fittings are essential for connecting plastic pipes to brass. These fittings come in various configurations, such as male-to-female or female-to-male threads. Ensure a secure and leak-free connection by using the appropriate transition fittings.

Compression and Threaded Adapters

Compression adapters provide a watertight seal between plastic and brass pipes. Threaded adapters allow for easy connection and disconnection. Use thread sealant or Teflon tape on threaded connections to prevent leaks.

Installation Process

Gathering Tools and Materials

Gather all necessary tools and materials before starting the installation. This includes pipe cutters, wrenches, thread sealant, Teflon tape, and the brass components. Having everything ready ensures a smooth and efficient process.

Cutting and Preparing Pipes

Cut the plastic and brass pipes to the required lengths using a pipe cutter. Ensure the cuts are clean and smooth to create a secure connection. Deburr the edges of the pipes to remove any roughness.

Connecting Pipes and Fittings

Connect the plastic and brass pipes using the transition fittings. Tighten the connections securely using a wrench. For compression fittings, ensure the compression ring is seated properly and tightened to create a watertight seal.

Testing for Leaks

After completing the connections, test the system for leaks. Turn on the water supply and check each connection point. Look for any signs of water leakage and tighten connections as needed.

Benefits of Brass Plumbing

Durability and Longevity

Brass plumbing offers superior durability and longevity compared to plastic. It resists corrosion, high temperatures, and pressures, ensuring a reliable and long-lasting plumbing system.

Improved Water Quality

Brass plumbing does not leach harmful chemicals into the water, unlike some plastic pipes. This ensures safe and clean water for household use.

Aesthetic Appeal

Brass plumbing adds a classic and elegant look to the plumbing system. It is often preferred for visible installations due to its aesthetic appeal.

Maintenance and Upkeep

Regular Inspections

Regularly inspect the brass plumbing system for any signs of wear or leaks. Early detection of issues prevents major problems and costly repairs.

Cleaning and Maintenance

Keep the brass fittings clean and free from corrosion. Use appropriate cleaning agents and avoid harsh chemicals that can damage the brass. Regular maintenance ensures the longevity of the plumbing system.

Replacing Worn Components

Replace any worn or damaged brass components promptly. This prevents leaks and maintains the integrity of the plumbing system.

Conclusion

Transitioning from plastic piping to brass plumbing offers numerous benefits, including enhanced durability, improved water quality, and aesthetic appeal. By carefully planning the transition, selecting the right brass components, and following proper installation techniques, you can create a reliable and long-lasting plumbing system. Regular maintenance and inspections ensure the system continues to perform efficiently, providing peace of mind and long-term value. Investing in brass plumbing is a wise choice for homeowners seeking a robust and sustainable plumbing solution.

Connect

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interest in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://ifanpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Recent Comments