Choosing the right PEX (cross-linked polyethylene) fittings is crucial for the success of your plumbing project. With various types available, selecting the appropriate fittings ensures a secure, leak-free, and durable plumbing system. Here’s a comprehensive guide to help you make the right choice.

Understand PEX Fitting Types

Different types of PEX fittings suit various applications and installation methods.

- Crimp Fittings: These use copper or stainless steel rings. They require a crimping tool for secure connections. Ideal for residential plumbing.

- Clamp Fittings: Similar to crimp fittings, but use stainless steel clamps. Suitable for tight spaces and easier to install.

- Push-Fit Fittings: These fittings don’t need special tools. Simply push the pipe into the fitting. Best for quick repairs and DIY projects.

- Expansion Fittings: These use a special expansion tool. They provide a very secure connection. Recommended for professional installations.

Consider Material Options

PEX fittings come in various materials, each with its own benefits.

- Brass Fittings: Durable and corrosion-resistant. Suitable for both hot and cold water systems.

- Plastic (Poly) Fittings: Lightweight and corrosion-resistant. Ideal for areas with aggressive water conditions.

- Stainless Steel Fittings: Extremely durable and corrosion-resistant. Best for high-pressure applications.

Match Fittings to PEX Type

Ensure the fittings match the type of PEX pipe you are using.

- PEX-A: Highly flexible, best with expansion fittings. Ideal for complex installations.

- PEX-B: Stiffer than PEX-A, works well with crimp and clamp fittings. Commonly used in residential plumbing.

- PEX-C: Least flexible, but still versatile. Compatible with crimp, clamp, and push-fit fittings.

Check for Certification and Standards

Use fittings that meet industry standards for safety and performance.

- NSF Certification: Ensures the fittings meet health and safety standards.

- ASTM Standards: Indicates the fittings comply with American Society for Testing and Materials standards.

Assess Pressure and Temperature Ratings

Choose fittings that can withstand the pressure and temperature requirements of your system.

- Pressure Rating: Ensure fittings can handle the maximum pressure of your plumbing system.

- Temperature Rating: Check that the fittings are rated for the temperature ranges they will encounter.

Ease of Installation

Consider the complexity of installation when choosing fittings.

- DIY Friendly: Push-fit fittings are ideal for DIY enthusiasts due to their simple installation.

- Professional Use: Expansion fittings require special tools and are best for professionals.

Cost Considerations

Balance cost with quality and suitability for your project.

- Budget: Crimp and clamp fittings are generally more affordable.

- Long-Term Value: Brass and stainless steel fittings, though more expensive, offer greater durability.

Application Specifics

Tailor your fitting choice to the specific application within your plumbing system.

- Potable Water Systems: Ensure fittings are safe for drinking water. Look for NSF certification.

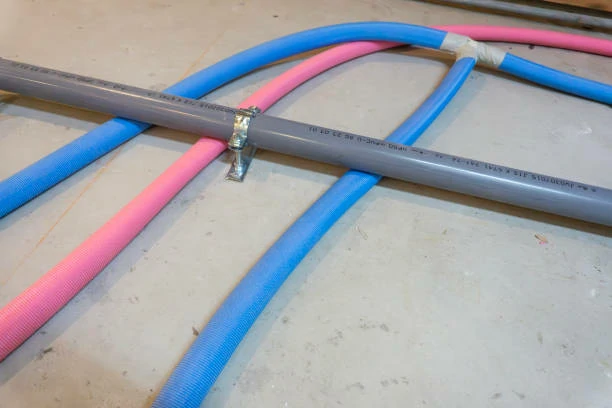

- Radiant Heating Systems: Use fittings that can handle higher temperatures and pressure.

- Outdoor Applications: Choose corrosion-resistant fittings like brass or stainless steel.

Compatibility with Other Systems

Ensure compatibility if your project involves connecting PEX to other types of piping.

- Transition Fittings: Use these to connect PEX to copper, PVC, or other materials.

- Universal Compatibility: Push-fit fittings often work well with multiple pipe types.

Longevity and Maintenance

Consider the long-term maintenance and replacement needs of your fittings.

- Durability: Stainless steel and brass fittings offer longer service life.

- Maintenance: Push-fit fittings can be easily disconnected for maintenance.

Environmental Factors

Account for environmental conditions that may affect the fittings.

- Exposure to Chemicals: In areas with high chemical exposure, use corrosion-resistant fittings.

- UV Exposure: Avoid exposing PEX fittings to direct sunlight for extended periods.

Seek Professional Advice

When in doubt, consult with a professional plumber or supplier.

- Expert Recommendations: Professionals can provide insights based on experience and specific project needs.

- Supplier Guidance: Reputable suppliers can recommend the best fittings for your requirements.

Conclusion

Choosing the right PEX fittings involves understanding fitting types, materials, certification, and compatibility with your specific application. By considering these factors, you can ensure a reliable, efficient, and long-lasting plumbing system. Proper selection of PEX fittings enhances the performance and durability of your plumbing project, providing peace of mind and long-term value.

Connect

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interest in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://ifanpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Recent Comments