A Comprehensive Guide to PEX Fitting

PEX (cross-linked polyethylene) has revolutionized plumbing with its flexibility, ease of installation, and durability. This guide explores PEX fittings, essential components in PEX plumbing systems, covering their types, uses, and advantages.

Understanding PEX Fitting

PEX fittings connect PEX pipes and ensure a secure, leak-free system. These fittings come in various types and materials, each designed for specific applications and installation methods.

Types of PEX Fitting

Different types of PEX fittings suit various plumbing needs. Here are the most common types:

- Crimp Fittings: Use metal rings and a crimping tool to secure the connection.

- Clamp (Cinch) Fittings: Utilize stainless steel clamps and a cinching tool.

- Push-Fit Fittings: Allow easy, tool-free installation.

- Compression Fittings: Use compression nuts and rings to create a seal.

- Expansion Fittings: Require expanding the PEX pipe and fitting it over the connector.

Materials of PEX Fitting

PEX fittings come in different materials, each with specific benefits and uses.

- Brass: Durable and corrosion-resistant, suitable for various applications.

- Plastic (Polymer): Lightweight and corrosion-free, often used in potable water systems.

- Stainless Steel: Offers high strength and corrosion resistance, ideal for commercial applications.

Crimp Fitting

Crimp fittings are popular due to their reliability and cost-effectiveness.

- Installation: Slide a metal crimp ring over the pipe, insert the fitting, and use a crimping tool to secure the ring.

- Advantages: Provides a secure, leak-proof connection. Suitable for most residential applications.

- Tools Required: Crimping tool, crimp rings, and a PEX cutter.

Clamp (Cinch) Fitting

Clamp fittings offer an alternative to crimp fittings with similar reliability.

- Installation: Place a stainless steel clamp over the pipe, insert the fitting, and use a cinching tool to tighten the clamp.

- Advantages: Easier to work with in tight spaces. Offers a secure connection.

- Tools Required: Cinching tool, stainless steel clamps, and a PEX cutter.

Push-Fit Fittings

Push-fit fittings provide quick and easy installation without special tools.

- Installation: Simply push the PEX pipe into the fitting until it clicks.

- Advantages: Ideal for DIY projects. Easy to install and remove.

- Tools Required: None, though a PEX cutter is useful for clean cuts.

Compression Fitting

Compression fittings create a strong seal using compression nuts and rings.

- Installation: Slide a compression nut and ring onto the pipe, insert the fitting, and tighten the nut.

- Advantages: Provides a secure connection. Useful in applications requiring frequent disassembly.

- Tools Required: Adjustable wrench and a PEX cutter.

Expansion Fitting

Expansion fittings expand the PEX pipe to fit over the connector.

- Installation: Use an expansion tool to enlarge the pipe, then fit it over the connector.

- Advantages: Creates a strong, leak-free connection. Suitable for cold climates due to pipe expansion capabilities.

- Tools Required: Expansion tool and a PEX cutter.

Choosing the Right PEX Fitting

Selecting the appropriate PEX fitting depends on several factors, including:

- Application: Determine the fitting type based on the specific plumbing need (e.g., potable water, radiant heating).

- Material Compatibility: Ensure the fitting material is compatible with the PEX pipe and the system requirements.

- Ease of Installation: Consider the tools and expertise required for installation.

- System Pressure and Temperature: Verify that the fitting can withstand the system’s pressure and temperature conditions.

Advantages of PEX Fitting

PEX fittings offer numerous benefits over traditional plumbing fittings:

- Flexibility: PEX pipes and fittings can navigate around obstacles, reducing the need for joints and elbows.

- Durability: PEX fittings resist corrosion, scaling, and chemical leaching.

- Cost-Effectiveness: PEX fittings and pipes are generally more affordable and easier to install, reducing labor costs.

- Leak Resistance: Properly installed PEX fittings provide a secure, leak-proof connection.

- Versatility: Suitable for various applications, including potable water, radiant heating, and snow melting systems.

Common Applications of PEX Fitting

PEX fittings are versatile and used in various plumbing applications:

- Residential Plumbing: Ideal for hot and cold water supply lines, offering flexibility and ease of installation.

- Radiant Floor Heating: PEX fittings connect PEX pipes in underfloor heating systems, providing efficient and even heat distribution.

- Snow Melting Systems: Used in outdoor snow melting systems to keep driveways and walkways clear of snow and ice.

- Commercial Plumbing: Suitable for commercial buildings, offering durability and ease of maintenance.

Maintenance and Troubleshooting

Proper maintenance ensures the longevity and performance of PEX fittings.

- Regular Inspection: Periodically check fittings for signs of wear, leaks, or damage.

- Leak Repair: Use a PEX cutter to remove damaged sections and replace them with new fittings.

- Tool Maintenance: Keep installation tools in good condition to ensure reliable connections.

Conclusion

PEX fittings are essential components in modern plumbing systems, offering flexibility, durability, and ease of installation. Understanding the different types of PEX fittings, their materials, and applications can help you choose the right fittings for your plumbing needs. Whether you’re a professional plumber or a DIY enthusiast, PEX fittings provide a reliable and cost-effective solution for various plumbing projects.

Connect

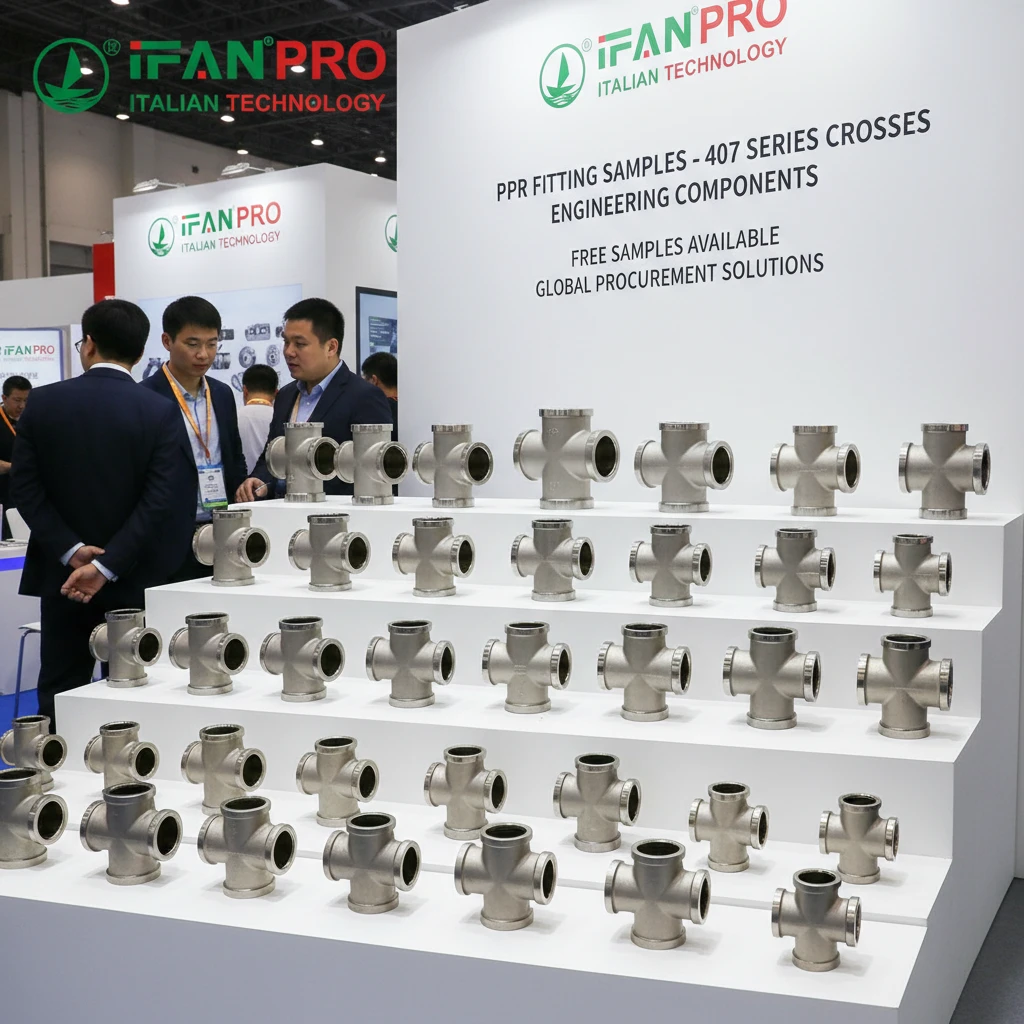

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interest in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://ifanpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Recent Comments